If you spend a lot of time metalworking, you should know the importance of safe dust collection. Dust explosions are common and can cause unnecessary harm to employees and costly equipment. The metal contaminants released have a very hazardous nature. They can pollute the air and make your shop unpleasant and dirty.

The extreme side of this scenario is that these hazards can cause dangerous thermal events. Financially, this is why it makes sense to buy high-quality dust collectors. These devices can safely gather metal grindings and place them away in a safe containment space. To ensure that dust collection is as safe as possible, you must know the best ways to operate and maintain these helpful machines. Purchasing the dust collector is one part.

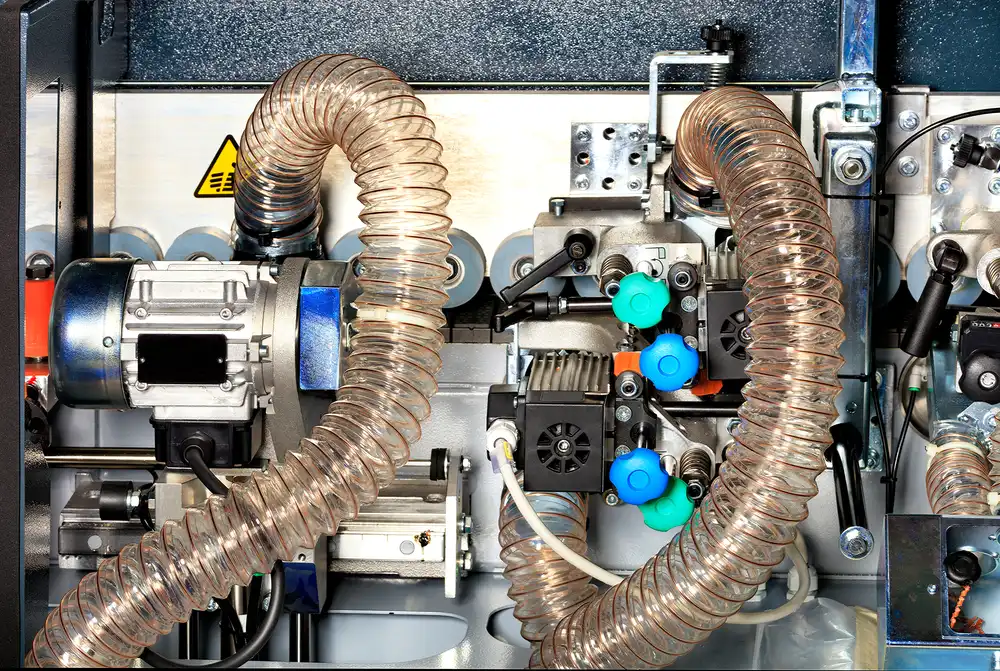

How Do Dust Collectors Work?

As a professional wood/metal worker, you will often have to deburr, finish or grind a ferrous or non-ferrous metal. The airborne metal debris emitted has the elements required to become combustible. These elements release small debris into the air after metal grinding. This dust is very harmful, and many organizations are required by law to regulate its disposal.

If not safely handled, this dust can cause several issues that affect general worker health and the cleanliness of your workspace. It can lead to hazardous fires and, in some cases, even explosions. To maintain a safe work environment, you must prioritize employee safety, sanitation, and air quality. You will find avoiding accidents will save you money in the long term even if you must invest big first.

It’s good to know that there are two primary types of dust collection filtration systems. You can find dry filtration and wet filtration. The dry filtration machines operate like vacuum cleaners, except they are much more significant. They have a simple job of sucking up and safely holding metal debris. The device will do this until it has reached its maximum storage capacity.

Wet filtration models are different because they use water to filter the debris. This means they force all of the metal grinding debris into a tank of water. This capturing and cooling technique will help reduce any potential risk of fires and explosions. The water neutralizes most of the threats involved. Taking extra safety measures is an investment that pays for itself. Wet filtration is more expensive, but it is highly recommended. Wet dust collection machines make life easy. The wet filtration is designed to be simple to operate and clean. Many consumers consider them an excellent choice for a range of metalworking operations.

Features and characteristics of a dust collector

The Cyclone

A cyclone is used to remove large pieces of wood that are sticky. It has no filter, so it is strong enough to handle abrasive or harsh materials. It is strictly for heavy material. The material must be heavy enough to fall out of the air stream. If it is too light, then the dust will easily pass through. Adding this to a wood dust collection system will help deal with the rougher materials that smaller filters might struggle to handle.

The Baghouse

A baghouse is a dust collector that has filters. Baghouses are designed with long cloth bags as filters. These cloth bags work wonders to mop up any dust on the surface. The technique used to keep them working efficiently are fans or compressed air. It is one of the most effective options, but this is a messy and high-maintenance method.

Baghouses have a specialty in capturing fibrous or sticky dust. The collector is built to handle hefty dust. You can also subject them to tolerate high temperatures. A significant disadvantage of this dust collector is that you need to work hard to change the bags. If you use it throughout the day, you could end up having to replace hundreds of loads.

The space available is another problem related to baghouses. To get the same surface area as the other options, you will need an extensive amount of large bags. If the space you work in is small, this might be a problem.

The Cartridge Collector

Woodworking professionals are using more cartridge collectors because they are helpful. A cartridge dust collector is a smaller option that provides a greater surface area for small working spaces. The working applications that involve very fine sawdust will benefit from this collector.

A cartridge dust collector has small enough filters to capture this fine dust. It works through high pressured pulses of compressed air. This traps the dust and cleans the filters at the same time. Many consumers appreciate this option because it provides a longer filter life. Cost-wise this goes a long way, especially when dealing with vertical cartridge collectors. It is the optimal option for trapping dust that contains contaminants.

Difference between wood and metal dust collector

A wood dust collector is often not made with a cooling mechanism. The wood is not as easily flammable as the metal when heated. Metal dust collectors will often have wet filtration systems that can help trap the metal and cool it in water.

Similarities

The metal and wood dust collectors can be fitted with different size filters to allow wood/metal dust containment.

Can you use a wood dust collector for metal?

A wood dust collector will eventually get cut up by the collected sharp metal shards. It will not serve the purpose for an extended period.

Can you use a metal dust collector for wood?

Yes. A metal dust collector will work well for wood. It is durable and has the cooling system required to contain chemical wood.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024