Polyester resin for wood turning

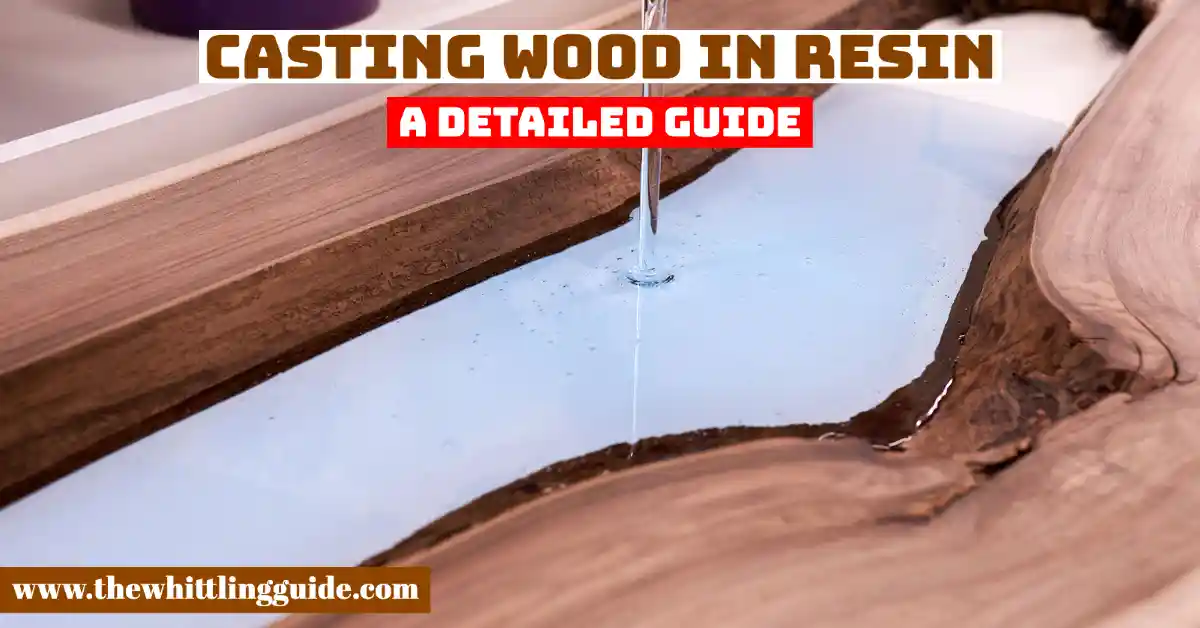

Casting wood in resin has been a popular technique for a hundred years. In this technique, a metal mold is cast into a resin. This process is most commonly used with metals such as bronze and brass. However, the technique is also used to cast resins such as polyester and polyurethane. The use of polyester and polyurethane resins in casting is called polymer casting and was first developed in the early 1980s. Polymer casting involves pouring molten resin into a cast iron mold.

Tools and materials

- GE 100% Silicone Caulking

- Caulking gun

- Silicone Oil

- Orbital Sander

- Sandpaper

- Grinding and polishing paste for glossy surfaces

- Polisher

- High-Quality Wood Oil

- Resin Mixing Cups and Stir Sticks

- Heat Gun

- Butane Torch

- Level

- Masking Tape

- Cloth

- Nitrile Gloves

- Respirator Mask

- Eye Protection

- The wood of your choice

Steps

- Prepare your wood before you start the process. Preparing means sanding and removing grease and dirt on the wood. Sand small pieces of wood by hand and large surfaces with an orbital sander. That prevents stress marks on your item.

- Use a bubble level to check if the surface is level. As the epoxy resin flows, it goes to the lowest part and will not spread as expected hence the need to maintain a level wooden surface.

- Gloves protect your skin from getting in contact with the fluid. —master, Put on your gloves, and mix the resin in a container. It contains two components, and that is the resin and hardener. It takes minutes to mix well, ensuring the curing process works as planned.

- Uniform fluidity is what you should aim for without streaks. Add the color of your choice. The mixing ratio is attached to the package. The ratios range from 1:1, 2:1, and 4:1. The epoxy resin comes with the resin and hardener in the exact amounts needed. Use a plastic or wooden spatula for mixing. Be careful when stirring since you will create bubbles.

- Apply the resin mixture.

Application

- Epoxy resin is a waterproof sealer for tabletops, wooden boards, and furniture. The resin has to cure so that it does not flow in any direction. You may get started with the application process when you have completed the above steps.

- Tap the edges, so the resin does not run over and drip onto the floor. Spread the wood resin using a spatula. Make sure you have made enough epoxy to cover the entire surface at once. It has to level out automatically.

- If there are air bubbles, remove them using a hot gun or torch. Practice on a test piece first before you work on large objects. It helps you understand the process and how to handle the product better. Master timing since you have a maximum of half an hour to seal the surface.

Best epoxy for woodturning

Epoxy Resin Crystal Clear

The Epoxy resin crystal gives a clear finish to your wood items and keeps them natural. It works on multiple wood items, such as tabletops and coffee tables. You are allowed to add color.

Support the tables to prevent flexing that causes cracking. Apply a water-based coat, let it cure, and apply the epoxy. Sand the surface for the epoxy to stick. The epoxy is UV resistant. It resists yellowing since it contains UV inhibitors. Do not use it on stained or treated wood.

However, that does not mean you should leave your items in direct sunlight or permanently outdoor use. It is food-safe, although each mixture has to be assessed. Properly cure the epoxy for safe use. It is self-leveling, and that makes the process bearable. It works better with mica powder (View Product).

Resin turning

Resin turns us into a process that involves a lot of stages. Wood pre is the starting point. How your wood turns depends on how much you prepare the wood. During preparation, clean and dry the wood. That creates a good bond between resin and wood.

Make a mold, and cut after the resin cures. Assemble the mold using hot-melt glue and screws. Remove the screws before cutting the mold. Size your mold and secure the wood. The Melamine-coated particleboard is affordable and easy to use.

Mix the resin and fill the mold. Put in the pigment using a separate mixing container and blend. Use a drill and paddle mixer to blend. Apply the mold quickly to avoid a cure before you finish. Avoid bubbles and voids. Cure under pressure and cut the mold-free. Remove the mold to free up the blank. Start turning.

Best resin for woodturning

Epoxy resin brings better results when compared to polyester and orthophthalic. Polyester smells awful and should be in well-ventilated areas, and polyurethane is bubbly. Epoxy resin works on both smaller and larger applications.

It is a thermosetting agent since it cures depending on temperature. Mix with a hardening agent for a chemical reaction. The result depends on the hardener used. However, epoxy does not buff to a shiny state. Add more resin for a glossy look.

Resin lathe

Using resin on a lathe is a new technology that requires skilled woodworkers to make multi-colored pieces in different shapes and sizes. The process includes spinning a piece of wood on a lathe using coloring agents, casting mold, sealing agents, chucks, vacuum chamber, and resin.

Take the liquid form of the resin and give yourself a base form to shape. You can turn resin only, add wood pieces, or wood seal. Lathe speed with tool pressure contributes to your result. Too much pressure on the resin leads to melting. Try woodturning with resin using a scrap before the actual project.

Woodturning glue

Use glue as a way of crafting wood. Glue pieces of wood together to create one block when attached to a lathe. Glue-ups give wooden blocks a mixture of grains. Cut the wood to make your shape.

Tools

- Measuring Tape

- Wood

- Sandpaper

- Saw

- Strong Wood Glue

- Clamp

Steps

- Clean the wood surface using sandpaper.

- Cut the wood using measurements depending on your project.

- Cut the wood in equal lengths using a saw.

- Place the wood into s block, align and fit flat against one another.

- Separate the wood and apply glue following the manufacturer’s instructions.

- Repeat the process and test rigidity. When solid, attach it to the lathe for turning.

Polyester resin for woodturning

Polyester resin has a bad smell. It is less powerful than epoxy and affordable. Hence it is used in a well-ventilated area. Polyester products are carcinogenic if inhaled, so be careful. Take proper precautions and wear a face mask.

There are two types of polyester resins, and these are orthophthalic and isophthalic. The first is for hobby and light commercial use, and the second is for marine construction.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024