CNC stands for Computerized Numerical Control and refers to a range of computer-controlled machines. A CNC machine control computer controls a CNC machine. A CNC controller is a programmable computer that sets the machine in motion based on its programming. The programming of the CNC machine computer makes these machines useful for various things, from milling wood to carving stone to carving foam.

In this post, we will be looking at CNC machine types.

What is a CNC Machine

CNC stands for Computer Numerical Control, the automated control of machining tools such as drills, lathes, mills, and 3D printers. These are manufacturing and industrial applications.

The manufacturing process run by the CNC machine involves computerized controls and machine tools used to remove material layers from a stock piece. These stock pieces come in wood, plastic, glass, or metal, and a CNC machine allows precision and accuracy in the production run.

CNC Router

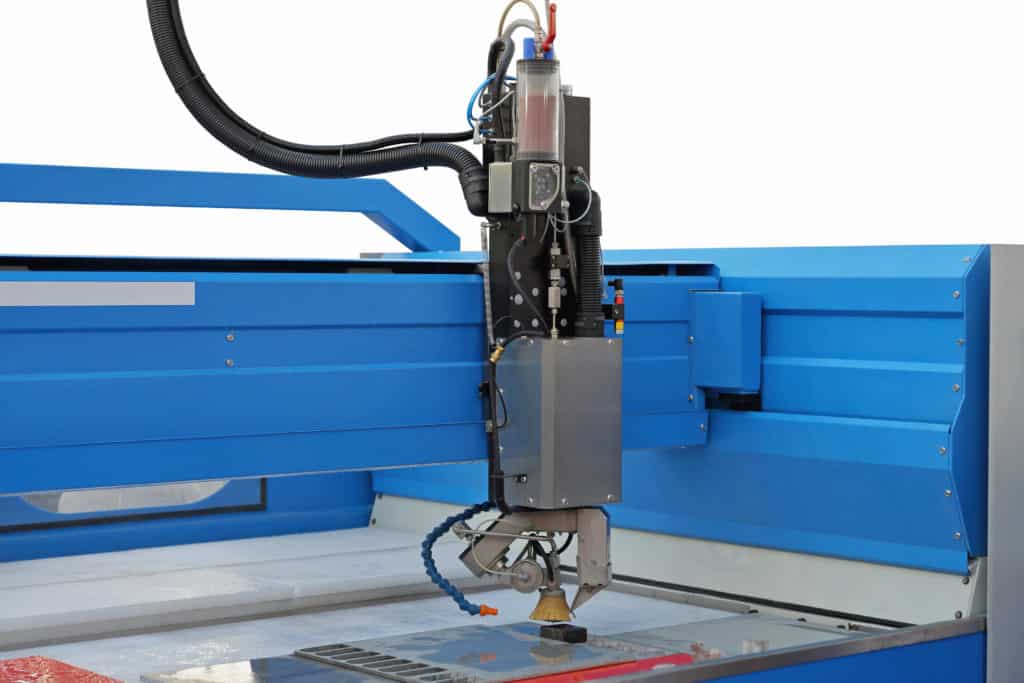

What is a CNC Router

A CNC router is a handheld router used for cutting multiple materials, and it cuts through steel, wood, aluminum, plastic, and foam. It is similar to a CNC mill as they both use a computer numerical control to route tool paths that allow the machine to start performing the task.

CNC routers decrease waste and increase production. They are fast and come in different sizes. Industrial CNC routers are big and use a large amount of space. However, there are desktop routers that use less space.

They are smaller to the extent that they use a desk. The only disadvantage of the desktop router is that it is not as powerful as the industrial router. It is perfect for home use, and you connect it to your home computer. T uses the software on your computer and programs it to perform specific production functions.

What can you do with a CNC router?

CNC routers are used for woodwork, crafting materials, and making art pieces. Woodworkers use CNC routers to cut and shape multiple pieces of wood. I had to use the router to design my rocking chair for the balcony at some point.

It easily cuts through maple wood for a project. The CAD and CAM software helps you control and operate your router. You make cuts at the precise angles of your choice. You use bolts and screws to attach the pieces of wood as you make your item.

CNC routers are for manufacturing centers and homes. I advise you to go for easy-to-assemble kits if you use the router for private projects at home. With time, innovative routers lessen the burden for you.

What can you not do with a CNC router?

- You cannot avoid computer viruses or system problems

- You cannot avoid inconsistent software settings

Price Range

Desktop CNC routers range from 1,500 to 5,000, standard routers range from 5,000 to 30,000, and high-end routers range up to 100,000. It is now a matter of your needs and your budget.

CNC Mill

What is a CNC Milling Machine

A CNC mill is a version of CNC machining that revolves around milling materials. Milling is almost similar to drilling or cutting, and it uses a cylindrical cutting tool that rotates in multiple directions. A milling cutter moves along various axes and creates various shapes, holes, and slots.

The mill moves in different directions for specific materials and shapes. CNC mills are categorized by the number of axes they operate, and an axis is labeled after a letter. The X and Y axes represent a horizontal movement of the mill’s workpiece, and the Z-axis is the vertical movement.

Standard CNC mills have three to five axes. There are technologically advanced CNC mills that use CAM programs for specific shapes, and these shapes are hard to obtain using a manual tool. A fluid pump is one of the innovative features of the mill that pumps fluid to the cutting tool during the production process.

What can you do with a CNC Mill?

CNC mills excel in prototyping, complex parts, and precision parts. They manipulate materials in a precise manner. Mill machines cut metal and wood materials like CNC routers, but it is precise.

That is the reason why it is popular in the industrial sector. Using a cutter, the CNC mill makes shapes, slots, and holes on materials.

Pro Tip: You may also be interested in How Does a CNC Milling Machine Work?

What can you not do with a CNC Mill

- You cannot control vibration

- You cannot fix the jamming problem using the mill

Price Range

The CNC mill ranges from 5,000 to 100,00 depending on the model you want, features, and budget.

CNC Plasma Cutter

What is a CNC Plasma Cutter

A CNC plasma cutter is a machine that cuts through electronically conductive materials using a computer to control and direct a hot plasma at the material. CNC plasma cutters cut through brass, copper, and steel.

It is for fabric and welding shops, and auto repair and restoration technicians also use it. The CNC plasma cutter has systems run by a computer to move the torch in different directions using numerical coding programmed into the computer.

The cutter machine comes in different sizes. They are accurate and operate at a maximum speed of 500 inches per minute. They need plasma gas and assist gas to function, and the type of gas depends on the type of material. They use oxygen, argon, hydrogen mix, compressed air, nitrogen, and methane.

What can you do with a CNC Plasma Cutter?

The cutting of thick steel and high-alloy steel is made easy. It cuts through sheet metals, metal signs, tubes, and pipes. It cuts electrically conductive materials. The cutting speeds are high, and that makes it fast and accurate. It also cuts underwater, and that reduces heating and noise levels.

What can you not do with a CNC Plasma Cutter?

- It does not cut above 160mm for dry and 120mm for underwater cutting.

- You cannot avoid noise when dry cutting

Price Range

A CNC plasma cutter ranges above 4,000.

Types of CNC control

Motion type NC

It works in a contouring system or point-to-point system. The contouring system works in a continuous path as it cuts the material and follows a contour of the part. The point-to-point control system involves the workpiece and tool being placed in a position so that the CNC tool starts processing the material. The machines used are known as milling, lathe, and routing machine. They involve drilling, tapping, and boring.

Control loop CNC

The loop control system is based on the Closed-loop system. It has feedback from the control system. It measures physical differences such as position and velocity. Voltage levels and the digital system have to be monitored. They are accurate and powerful due to the monitoring condition that gives you room for adjustments. The open-loop system has instructions converted to signals by the controller. The use of servo amplifiers provides energy to the servo motors.

Number of Axis type CNC

The two-axis control system gives you access to the X and Z axis. The rotating tool moves in two directions. A two-and-a-half-axis control system is a three-axis machine. That is for drilling and tapping machines, also known as 2.5 axis machines.

The three-axis control system is three-dimensional and moves in the X, Y, and Z direction. They gained popularity in producing accurate precision parts. The four-axis and five-axis control systems have extra rotation on the maximum axis.

Types of Numerical Control

Traditional numerical control

Traditional numeric control is the use of punched paper tapes or cards. You have to load the paper tapes manually for each new part. There is no editing that takes place, and that increases your production time.

Computer numerical control

The CNC is a computer-based system. The required data is stored in the computer. It keeps large programs that the tapes cannot handle. It is a more dimensional machine system that allows the editing of programs.

Distributed numerical control

The DNC is a modern system of processing materials. It is almost similar to the CNC. The only difference is that you operate the machine using a remote computer to control multiple CNC machines. The remote computer hosts several programs and downloads the programs feeding instructions to the other computers.

Types of CNC software

Computer-aided design (CAD) Software

These programs draft and produce 2D vectors or 3D solid parts and surfaces. The model by a CAD program is operated by a CAM program to produce the final part using a CNC machining method.

Computer-aided manufacturing (CAM) Software

It is a set of programs that extract technical information from the CAN model and generate a machine program that runs the CNC machine. It manipulates the tool to produce a custom-designed part. The CAM software allows the CNC machine to run without operator assistance.

Computer-aided engineering (CAE) Software

Engineers use these programs for processing, analyzing, and post-processing stages of the development process. It assists tools in running the engineering process. The types of CAE software include finite element analysis, computational fluid dynamics, and multi-body dynamics software. See our Wood Router Buying Guide.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024