CNC machining techniques are the foundation for many woodworking projects that require precision, accuracy, and attention to detail. The development of the CNC router has made CNC machining techniques more accessible than ever before. A CNC router (or router) is used to carve, cut or engrave wood and other materials. A CNC router is a computer-programmable cutter that can be controlled by a computer or manually. This allows a CNC router to cut shapes in any material and size.

CNC Technology

CNC technology is the machining process whereby the latest computer numerical techniques. Machines are automated and controlled by a computer to work on the material. That is how the part is made, and that reduces work time and cost.

The computer converts a design by Computer-Aided Design software into numbers. The numbers coordinate a graph and control the movement of the cutter, and the computer contains the cuts and shapes of the material. The technology excels in creating identical parts from the same material.

Materials are in three directions, and the cutter is from one coordinate to the other. The directions are in letters. The X, Y, and Z-axis control represent the cutter’s movement on the CNC machine.

Designing in AutoCAD

AutoCAD is the use of a computer system for creating and modifying a design. It has both 2D and 3D drawings used for the construction and manufacturing of items. The professional drafting of designs is with detailed measurement for accuracy.

The information on the conceptual design has to be decoded and processed for the layout of the final product. The CAD software is modified with the given applications, and tool settings are for precision. The AutoCAD system increases productivity, improves the design, creates a database for the manufacturing process, and improves communication through documentation.

Before the software, engineers had to use drafters and sheets to make a replica of the design. That was time-consuming and the creation of scrapes. You are allowed to save and edit designs before the final product.

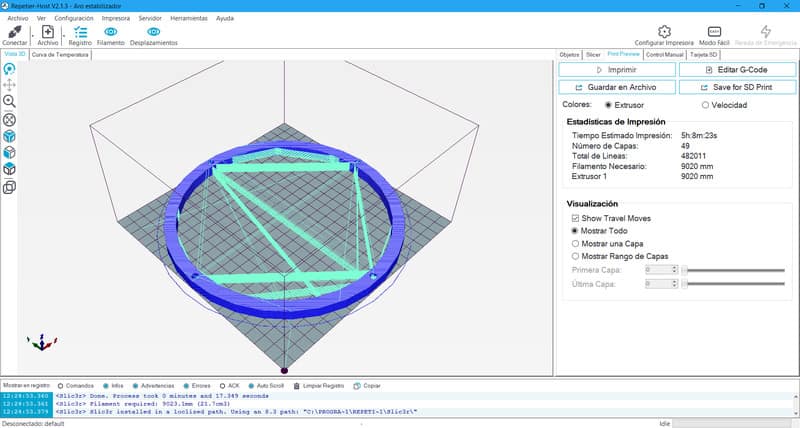

G-code

The G-code is the programming language from a computer used to control CNC machines. The program consists of several codes and data that tell the machine the dos and don’ts. A combination of the codes and the right tools results in correct and accurate repeatable parts construction.

Repeatable parts are hard manually hence the introduction of automated machines controlled by computers. The G-code creates consistency in the manufacturing process.

The machines become flexible as they allow you to amend and produce different parts using your preferred designs. The software programming controls the CNC machine clearly and logically, which is the power of software in the manufacturing industry.

CNC Machining

CNC stands for Computer Numerical Control, which is the automated control of machining tools such as drills, lathes, mills, and 3D printers. These are manufacturing and industrial applications.

The manufacturing process run by the CNC machine involves computerized controls and machine tools used for removing layers of material from a stock piece. These stock pieces come in wood, plastic, glass, or metal form, and a CNC machine allows precision and accuracy in the production run.

CNC machining for cutting wood

When using the CNC machine for cutting wood, you have to make sure there are holes drilled in the same spot on the pieces that go through the machine. The computer instructs the CNC machine to move along the piece of wood.

The computer directs the amount of pressure and cutting speed, which is why production increases. A perfect cut is what you get on every piece from the CNC machine.

What maximizes production is precision in cuts. The user has to start with a piece of material that comes as wood, and the output of the material can be as simple as drilling a hole. As long as there is the removal of material taking place, that is a manufacturing process.

Machining a dovetail joint

You have to draw a dovetail joint by making a wood joint drawing. Draw the wood joint using five dovetails on VCarve Pro. That is ShopBot’s software. The first toolpath is for taking off material with a ¼ bit, and tool path 2 has a 73degree dovetail router bit. The next stage is making the half-blind dovetails. Wood pieces have to be of the same height. Upload the G-code into the CNC and use the ¼ bit to make a clean cut. The last stage involves making the dovetail by combining the male and female parts.

Machining a mortise and tenon joint

You join two boards along the long edge. Both boards need a groove along one edge and a tongue that fits onto the other edge.

They need shaping so that they give a perfect finish. The joints have to be laid for cutting and shaping. The tenon has to range from 3-1/2 thick to the stock from which it originated. The mortise gauge is on to the tenon.

The lines drawn should be equal on both sides. A router cuts the material, and the mortise depth must be three times thicker than the tenon. There are several ways of cutting it, and you choose the easy way. Glue joins the mortise and tenon joints.

Machining a box joint

You cut out pins and tails on a flat board so that the inside corners become rounded. Make a jig that sits on the end of the machine. It holds the wood in a vertical direction to avoid making a clumsy cut.

A square piece from the stock is attached using a bolt to the end of the spoil board. The pocket cut has to be bigger than the wood piece you are using. Design the joint operating software of your choice. Run the tool paths, and you have a clean joint.

Pro Tip: Find out How a CNC Milling Machine Works.

Machining a cube

Design a cube using your dimensions and draw circles on each face. The depth of the circular pockets depends on what you want. Enter the dimensions on the side of the cube and radius to get the depth value.

Open DesignSpark options as you change the default behavior to cut. Use the pull tool to cut the holes in the solid.

Machining a sphere

You make use of a computer drafting program to set up an angle. The cutting edge faces inwards, and the tool has to be set at an angle. The part rotates under the device, and a spherical surface is made.

Toolpath Concepts

There is the X, Y, and Z allowance that represent the amount of material remaining. On a part to be removed later. The stepover is the material removed from the left or right side using a cutting tool.

The top of the stock is the stock used to make the part. The feed height is the height that the tool takes before feeding. Retract height is the height the tool retracts between moves. Clearance height is the height the device moves between operations.

The tool path centerline is the path taken by the tool as it moves along a tool path.

Toolpath Techniques

Facing

The facing removes excess material from the flat face of a part.

2D Contouring

That is the rough and the finish of the outside walls of a part.

Pocketing

It is a way of removing excess material from a shaped pocket.

Slot milling

That is the process of machining slots to maximize material removal.

Understanding the tool

You have to understand the directions in which the tool takes. The cutting tool has to rotate in a certain way that matches the material or part made. Since the tools make complex parts, you have to understand the technology that comes with your equipment.

There are types of machines that work on different materials—an improper tool results in inaccurate results and waste of material. See our post on CNC Machine vs 3d Printer.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024