How much do cnc machines cost?

A good-quality personal CNC machine ranges from $1,000 to $5,000. Match your desired features with the machines in your budget range. There are thousands of CNC machines available in the market at different prices.

High-end CNC Machines such as 5-axis robotic CNCs manufacture high-end military equipment, like aerospace/defence manufacturing companies. They cost up to a million dollars. You can get an entry-level hobbyist CNC 3018 for a price as low as $150.

The quality, speed, and versatility of the machine determine its worth. CNC Machines intended to be used on wood are more affordable than CNCs that mill ferrous metals such as tool steel and stainless steel.

Is a CNC machine worth it?

CNC machinery is an investment, but you might not see its worth if you fail to use it properly. If you ever consider modern manufacturing, you should go for a CNC machine. The manufacturing starts from major assembly lines to small tool-and-die shops, and almost every industry uses CNC machines. That is from mini-mills in high-end scientific labs to the automotive industry.

CNC machines are not only used by manufacturers but also engineers. They help produce more complex parts than the average cutter can handle. Gather everything you need to know to purchase your milling machine with confidence.

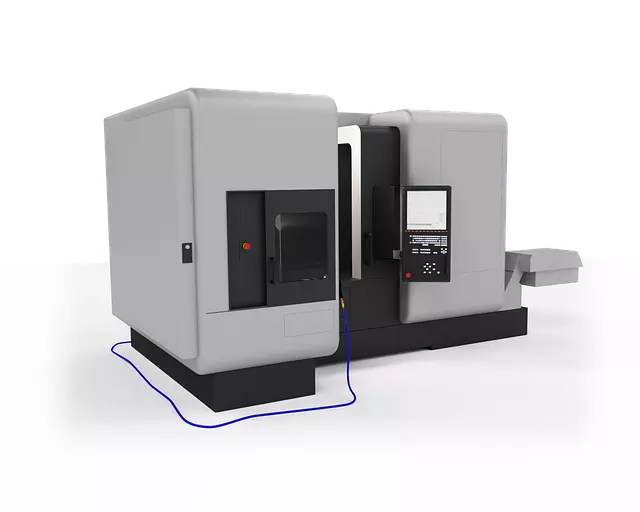

CNC machines are powered machine tools designed to carve material. They use multiple cutting tools, including rotating blades, drills, and abrasives. They feature high-quality cast iron construction, variable speed engines, power feeds, and cutting tools that move along the x- and y-axis for maximum performance. They are in a variety of roles, from woodworking to metalworking.

What is the CNC price?

The cost of a CNC machine can vary significantly depending on its size, complexity, speed and versatility. Entry-level CNC machines can be purchased for as little as $150, while high-end, industrial-grade models can cost $100,000 or more.

It’s important to note that the price of a CNC machine depends on your specific needs and budget. For example, a less expensive model may be suitable if you plan to use the machine for simple hobby projects. On the other hand, if you need a machine for professional use or complex manufacturing tasks, a higher-end model with advanced features and capabilities may be required.

Before you buy, compare prices and features from different manufacturers and suppliers to find the best value for your money. This way, you can ensure that you get the right CNC machine for your needs at a price that fits your budget.

Factors Affecting CNC Machine Cost

Material of the parts

Different materials take a longer machining time compared to others. Just like steel and its alloys may take longer than copper during machining. The manufacturer spends more resources on machining steel than copper.

The price for steel parts becomes higher compared to that of copper. The harder the material is, the higher the price. The availability of the material plays into the cost. Scarce materials are less affordable and take longer machining time, adding up the cost.

Equipment used in production

The machines used in the production of different parts determine the cost. If the manufacturer does not have all the required CNC machines, there is a need for extra costs of outsourcing the needed machinery to complete the task.

If the process depreciates the machine, the final price is affected. That is why some small parts are less affordable.

Complexity and size

Ease of use makes the cost of your CNC machine bearable. The complexity of a CNC machine part increases the time used in its production. That is how you incur costs in production. Carving out some designs and shapes requires more machines and processes. That means loosening your budget.

The more complex your task, the more you pay. The size of the production part also accounts for the costs. The larger the CNC part, the more material is used. That means taking more time. Large CNC parts require more machines to complete the finishing. That increases their cost, and the chances are high that small CNC machines are more affordable than larger parts.

Number of parts produced

Ordering bulk productions of the part requires more lessons than buying each separately. The process is cheaper when producing large volumes than individual CNC parts.

More parts mean machines are automatic, and labor costs decrease. Small orders may require manmade production, and this increases the costs involved.

Tolerance required

As you aim for precision in your tasks, the process comes at a cost. Manufacturers increase their prices concerning the tolerance level you need.

The manufacturer uses a different set of equipment and tools for higher precision. That takes a lot more time to come up with the accuracy required. That means more costs.

How much does a mini CNC machine cost?

The cost of a mini CNC machine can vary depending on brand, features and quality. Entry-level mini CNC machines typically start at about $150, while high-end models with advanced features and capabilities can cost up to $1,000 or more.

It’s important to note that low-end mini CNC machines may have limited features and may not be suitable for more complex tasks. Conversely, high-end models may have more advanced features and capabilities that are more suitable for professional use.

Ultimately, the cost of a mini CNC machine will depend on your specific needs and budget. Before purchasing, research and compare prices and features from different manufacturers and suppliers to find the best value for your investment.

How much is a CNC machine for metal?

The price of a CNC machine for metal can vary significantly depending on the machine’s size, complexity and functionality. CNC machines for metalworking can range from a few thousand dollars for entry-level machines to hundreds of thousands for more advanced models.

It’s important to note that some complete CNC machine packages include only the most basic components needed to produce simple metal parts. Therefore, it’s important to carefully consider your specific needs and budget when selecting a CNC machine for metal fabrication. Without proper knowledge and budget planning, you may spend too much money on a CNC machine that is too complex or expensive for your needs.

Ultimately, the cost of a CNC machine for metal depends on your specific needs, and it’s recommended that you research and compare the prices and features of different manufacturers and suppliers to find the best value for your money.

How much is a CNC machine for wood?

The cost of a CNC woodworking machine can vary widely depending on several factors, including the machine’s size, power, features and brand. The price range for a CNC woodworking machine is between $2,000 and $50,000. However, the price may vary depending on the specific model and where you buy it.

It’s important to know that lower-end CNC machines may have fewer features and be less powerful than higher-end models. Therefore, it’s a good idea to compare prices from different stores before buying and carefully check what features each model offers to ensure you’re getting the best value for your money. Ultimately, the price of a CNC machine for wood depends on your specific needs and budget.

What is the easiest CNC machine to use?

BobsCNC Evolution 4 CNC Router Kit with the Router

It features a rigid laser cut frame, SG20U supported rail system, a GT2 belt drive on the X and Y axis, and ACME TR8 on the Z-axis. It comes with an excellent design and rigidity. It has the Makita RT701C router and Arduino-based microprocessor that uses gbrl and is connected to a communication port via a USB connection. That makes it an ideal machine for beginners.

What makes it one of the best 3d CNC machines is its versatility. It runs on different software such as Windows, OSX, Linux, and Raspberry Pi. It is also ideal for beginners because it is easy to assemble.

It comes with an assembler manual, which you get from their site. However, the process of assembling is time-consuming. It is easier to learn the machine through the process of assembling.

As much as it is easy to use, it does not compromise quality. It is a CNC machine for the money. It is precise and accurate. The instructions are easy to understand (See Price and Review).

Why is CNC so expensive?

The Specifics of Your Order

The cost of a CNC machine can vary widely and depends on several factors. The specific components and materials used in the machine’s construction can significantly impact the price. Entry-level CNC machines tend to be less expensive than high-end machines because they generally have less powerful components and are made from less expensive materials. On the other hand, high-end CNC machines often have more powerful components and are made from higher quality materials, which can increase their cost.

In addition to the machine’s basic design, other factors can contribute to the price of a CNC machine. For example, the level of automation and precision the machine can achieve can also affect the price. Ultimately, the price of a CNC machine depends on various factors, including the specific features and capabilities you need for your particular application.

The Cost of Your Materials

The Cost of your material determines the overall cost. If it is affordable, the machine becomes affordable as well. Unfortunately, it is up to the manufacturer which type of material to use on a CNC machine.

Thinking About Labor Costs

The labor required when making a CNC machine makes it less affordable. There is a need at some point for specialists during the process. That means you cannot have one specialist fixing the whole machine.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024