Can you machine aluminum on a wood lathe?

Machining aluminum on a wood lathe is dangerous, especially when freehand. You must take the required precautions. Ensure that when you start machining, the workpiece is sturdy and secure. You want to avoid being hit with any chunks of metal flying out of the lathe.

Aluminum shards can do more damage than lumps of wood will. Many unfortunate eye injuries occur because of this hazard. You must be aware because aluminum swarf can cut or burn the skin. When you machine aluminum, some long strings of metal might catch your hands.

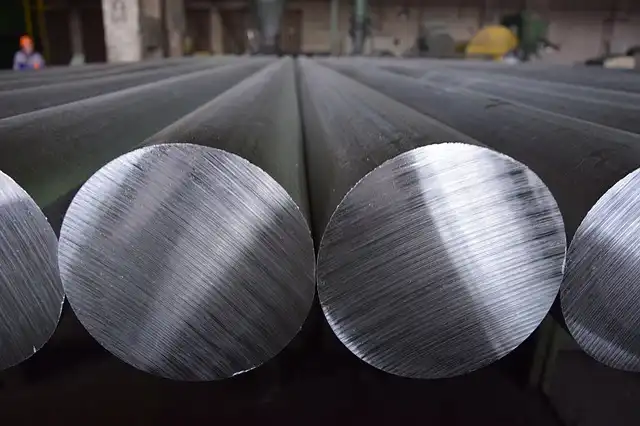

It is possible to machine mainly non-ferrous metals without much problem when using a wood lathe. It can produce a sufficiently high speed to cut the metals, but you need to stay in control. Brass, Copper, aluminum, and other soft metals will not be difficult to machine.

Turning aluminum on a wood lathe

Traditionally, a wood lathe does not turn metal. Turning aluminum on a wood lathe can be achieved with the correct knowledge and technique. The tool holder has been made to withstand some unscripted, heavily-built engineering initiatives. You will have to ensure the lathe clamps are solid and rigidly secured to the cutting tool. This placement will help ensure the mechanics of the devices can quickly turn small items.

Aside from just aluminum, you can also turn brass or steel freehand. It is quite a handy method for amateur workers who wish to produce creative projects without massive space and budget. You should be able to turn the aluminum as though it was wood. It would help if you made a few considerations before you begin, mainly related to safety. The first is that it is not very easy to hold the tool in your hand while cutting if you have little experience.

Shaky hands can be dangerous because cutting the aluminum will have some vibrations. The aluminum metal is rigid and can be resistant to the cutter tool. The beat may end up causing rough or ridged marks on your workpiece. This is extremely difficult when operating with freehand. You can expect decreased levels of accuracy from this.

Interrupted cuts, such as turning the corners off square stock, are difficult freehand. It is hard to control the cutting tool.

Convert your wood lathe to turn metal

If you have a high-quality wood-turning lathe, then you should be able to do most of your metal turning on this machine as well. A good wood lathe can perform boring, milling, and facing if you make minor tweaks to the device. Mounting a lathe is not tricky except. You have to be aware of the technique to attach the smaller cross slide.

This links directly with the lathe bed and needs to be mounted. You will need a kit that includes a hold-down screw or sud and a key for alignment. To help you get the margins done accurately, you will also need a spacer block. The block you choose should have a dimension of at least 1/2 inch. The swing should be around 8 inches.

wood and metal lathe combo

A combination of wood and metal lathe is a great way to save costs and space for amateur workers. It has different advantages that will boost your productivity. With the appropriate technique and the proper knowledge to use it, you can make a broader range of items.

These combo lathes are known as ‘Mother of Machine Tools.’ They can handle almost any task. You will not have to worry about switching between different tools to turn other metals. Using a combo machine will save you time and effort.

How do you spin metal on a lathe?

To spin metal on a lathe, you first build and install a fulcrum. A fulcrum can be described as a holding device that fits directly into the lathe. You can design this with a solid metal bar. The metal bar will be placed through a secure slot and attached with a complimentary bar. You can then use a wrench to bolt this bar when it is in place. You can bolt the bar to the underside of the lathe bed. The combination of these tasks should help you to form a stable bridge.

The next stage of the process involves working on the chuck. The chuck is a part that is used for clamping the workpiece. Make sure this is bolted and reinforced with a metal backplate before you start turning. If the lathe did not come with one, you might need to install this. An adjustable sliding tailstock may also help make the cutting process more efficient.

The final stage involves the forming tool. The forming tool you use will need to be made out of steel rods. This design is vital to help account for the intended component design.

How do you turn aluminum on a lathe?

Aluminum can be turned in the same way you would turn regular wood. If you have a high-quality lathe, it should handle the aluminum easily. It would be best if you still were prepared for the excessive vibrations that may occur.

What materials can be turned on a wood lathe?

Materials like aluminum, steel, and titanium to plastics, wax, and Delrin can be turned on a lathe.

How do you prepare stock for a wood lathe?

1. Remove any potential hazards from the wood

Check that there are no hazards with a thorough examination. Look for signs that harmful metal shards are not embedded in the wood. For the most accurate option, you can use a handheld metal detector. Take off all the hazards you can see before you start to cut.

2. Rough cuts

Cut your wood into small, manageable pieces. Dry wood is easier to cut. Please do your best to trim or split your wood early to help it dry faster.

3. Sealing the wood

It would help if you considered using a wood sealer or wax to prevent moisture from penetrating the wood. It has the potential to rot if not properly sealed.

How do you turn a square stock on a wood lathe?

In most cases, there will be no need to cut the timber. A square blank might be easier to use, but sometimes the difference can’t be noted. The easiest way to do this quickly is to clean up the ends and mount the timber. Between centers, grab your spindle roughing gouge or bowl gouge and have a go at it.

Can you turn soft metals on a wood lathe?

Non-ferrous metals such as brass are soft and can be turned.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024