Wondering how to charge for CNC plasma cutting? When someone contacts you for a plasma cutting job, they want to use your skills and tools to create something they want. That means you can charge whatever price you want, and the customer has no choice but to go for it. That does not mean you are being unfair. It just means that you respect both the value of your skills and the cost of your time.

Many people who own a CNC machine end up leaving it in the corner, never to be used, because they are overwhelmed by the process of charging for CNC plasma cutting. Here is a guide to help ease that pain and help you start charging for CNC plasma cutting.

What can you cut with a CNC Plasma Cutter?

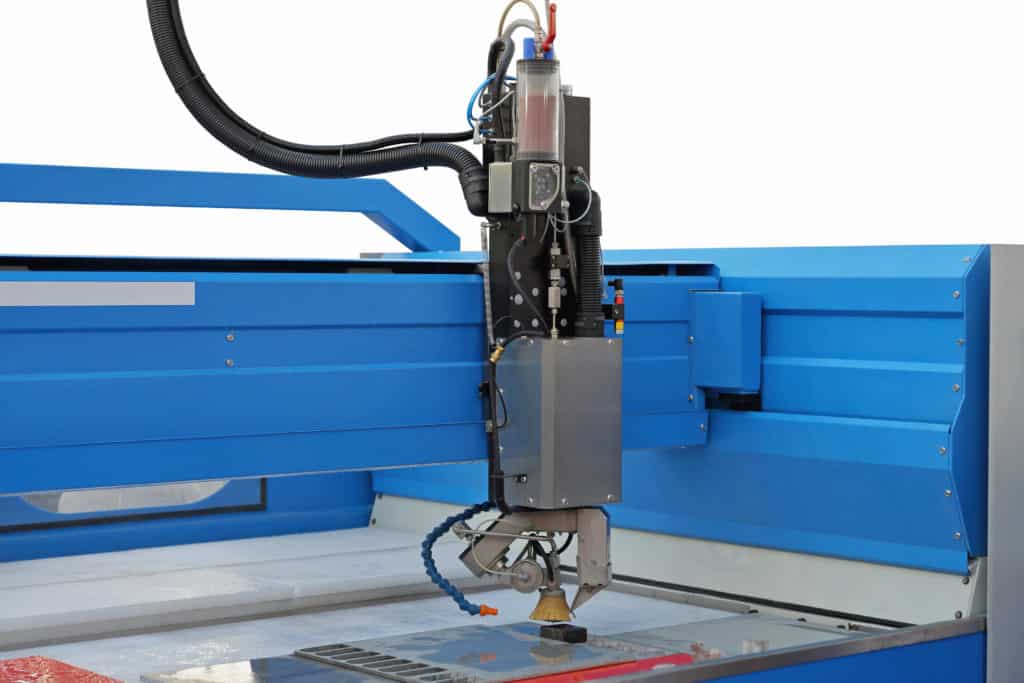

A CNC plasma cutter cuts electrically conductive materials. It uses an accelerated jet of hot plasma. The materials cut by a CNC plasma cutter are steel, aluminum, brass, copper, and stainless steel. It uses a cutting tool called a plasma torch.

A plasma cutter is for manufacturing, automotive repair, and industrial construction. The high-speed and precise cut cutter uses conductive gas of 30,000 Degrees Celsius. The plasma cutter performs in welding and cutting processes. The compressed gas used by the CNC plasma cutter includes oxygen and air.

It is blown onto the material at high speed through a nozzle. Enough heat is created that melts through a workpiece. That is how the material is separated. The efficiency of the plasma cutter is in the way it cuts both thin and thick material. Hand torches cut up to 38mm thick steel sheet.

Heavy-duty, computer-controlled torches cut up to 150mm thick steel sheets. Its performance does not change with the change in material thickness. It also cuts through high-strength structural steel with low heat. The cutting speeds are impressive. The underwater cutting process works on low heat exposure and reduces noise. However, the process consumes more power. Dry cutting produces noise.

Where to use a CNC Plasma Cutter?

Using a CNC plasma cutter depends on the type of cutter and the type of material. There are manual plasma cutters and mechanized plasma cutters. Manual plasma cutters are for workshops or thin metal processing, factory, agricultural and welding maintenance.

Mechanized plasma cutters work with cutting tables. They vary in size depending on the table and portal used. A hand-held plasma cutter is portable to carry and move around. That makes it faster when cutting material. It is ideal for home use.

CNC plasma cutters create decorative metalwork in workshops. That is the commercial purpose of the art sector. It is also for fabrication, welding, auto, and restoration industries.

Where to get materials?

The material processed using a CNC plasma cutter differs from the cutter type and your needs. You can get the material from a wide range of sellers. It is unlike business walking around picking old stuff for commercial purposes.

There are standards to follow for a business. For metal art, you are allowed to recycle or use old items. You have these items in your backyard or your garage.

Cost of a CNC Plasma Cutter

The type, size, and features determine the cost of a CNC plasma cutter. A CNC plasma cutter ranges from 15,000 to 300,000. You still get a wide range of good-quality CNC plasma cutters below 100,000. The value of the plasma cutter lies in what you prefer as a user. There are cutters above your budget, but that does not mean they are way more advanced than what you can afford.

What is important is selecting a wide range within your budget, list your needs, and start comparing. You need to consider cut quality, precision, and production rate. When considering the production cost, you have to look at the power, gases, abrasive, and regular maintenance costs. That tells you the type of plasma cutter that falls within your budget. The [production rate is the total cost you need to finish a project.

That also consists of the number of parts completed in a certain period. A plasma cutter for home use does not require high production. A workshop needs a fast plasma cutter.

You need to evaluate the number of tools accommodated by the cutter. The cut edge quality is the squareness of the finished edge. The flexibility of the plasma cutter is on the number of materials accommodated by the plasma cutter. That determines your decision.

The plasma cutter works on conductive metals. However, you need to compare the type of material and the strengths of the plasma cutter. The above comparison points to the plasma cutter of your choice.

Three tips to make money

Start a hobby shop

A hobby shop not only gives you space to do what you love but also helps you grow professionally and artistically. A hobby shop requires skills in plasma cutting and metal artwork. Either you get employed in a hobby shop or start your own.

Create a workstation

A workstation does not only create a central point for your clients but also shapes your passion. I prefer an industrial workshop that gives you more space to run bigger projects and storage. You have space that allows you to be flexible without limitations.

You have storage space for your tools and stock. Even if you are still growing and do not have enough capital, you can sell your skill and expertise in the industry. That does not only benefit the company, but it makes you grow.

Create metal art

Metal art pieces are popular in the metalwork industry. You run it in your backyard, home shop, or a small workshop. Metal designs show creativity and bring life.

They are unique, and people keep looking for art pieces. The skill requires you to cut any shape and be creative. You are not limited as you can make feather art pieces and artwork made of animals, wildlife, and steel. Confidence is the starting point. You have a wide market of professionals, kids, and homeowners.

How to charge for CNC plasma cutting

Offering your customers discounts for placing large orders goes a long way. You can charge per job, time, or by dimensions. You can also charge a flat rate per day, week, or month.

CNC Software

The CNC software creates program codes and instructions to run the CNC tool. It helps the machine understand function and design. The design is known as Computer-aided design software. The design is a language that the machine understands.

The language is known as a Computer-aided manufacturing software program. The CNC software increases automation, accuracy, and consistency. That increases the production in businesses and effective customer service.

Selling your items

You can sell your items that are known as metal artwork. These are masterpieces made of steel, animal skin, and feathers. That does not mean you have to build a shop to start selling. That takes place in your backyard for a start.

Artwork is not only about creating new items from new materials. You use old materials such as a saw, a tree trunk, or a cupboard. Amongst the items are yard art, signs, outdoor furniture, indoor décor, and gates.

Signs are for home use, business owners, and schools. You can make fire pits, fireplace screens, or garden gates using what you have and additional pieces. Here’s our post on How to Use a CNC Plasma Cutter

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024