Joints are important when doing a woodworking project because they allow the carpenter to assemble various components of a piece into an appealing object. Your project will be structurally sound, and you will have quality work.

Choosing the type of wood joint can be difficult for beginners. Paying attention to each wood joint is one of the most important aspects to master because almost all projects have some joint. Joinery is about combining pieces of wood or lumber to create more complex items.

Wood joints add strength, flexibility, toughness, and appearance to the project. Your joints should have these characteristics. Some wood joints use fasteners, adhesives, or ties, while others use only wood elements.

Wood joints join pieces of wood together to form intricate pieces. Depending on the type of wood joint, there are different techniques for making joints. Types of wood joints include butt joint, cookie joint, bridle, filet, dovetail, finger joint, lap joint, mortise joint, pocket hole joint, rabbet, and tongue and groove joint.

Wood joints add rigidity to jobs, improve appearance, and strengthen parts. Mechanical fasteners and adhesives secure the joints. Even applying glue, you can easily undo the joints with steam. Use wood fasteners and glue them together to strengthen the joint. However, some joints work without glue or a fastener. Below you can see a detailed study of the connections.

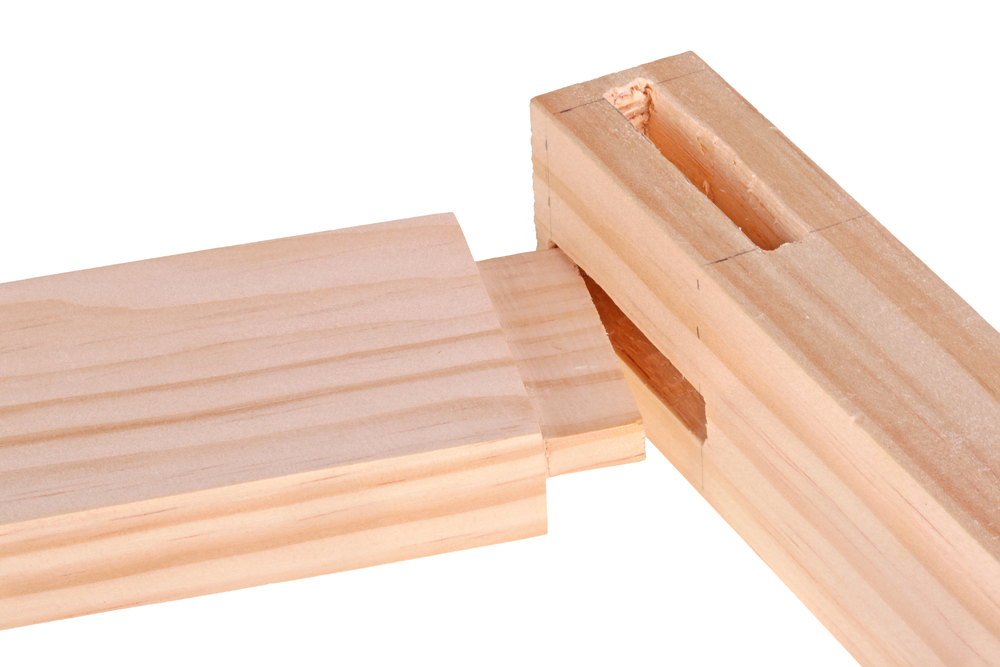

Mortise and Tenon Joints

Mortise and tenon joints are well-known for their strength. The wood joint does not butt both pieces together. It requires one piece of wood to be inserted into the other. The receiving wood piece has a hole or cavity in the surface known as the mortise.

The opposite piece has a carved nub on its end, called the tenon, inserted. It has a sturdier hold than the butt joint. The tenon measures 1/3 of the wood’s thickness, with the mortise corresponding to the height and width of the tenon. It works in heirloom cabinetry for furniture such as dressers and cabinets (Heirloomscabinetry.com).

Mortise and tenon joints join two pieces of wood at 90 degrees. One end of the piece is inserted into a hole in the other wood piece. Apply glue to this wood joint, and a pin or wedge to lock it in place. Some mortise slots are open, allowing the tenon to pass through the material, while others hide the end of the tenon inside the mortise space. Mortise-and-tenon joints go into many types of projects. That is from rustic carpentry to fine furniture making.

Terms to describe different types of mortise-and-tenon joints vary by region and even from woodworker to woodworker. There are four variations a beginner woodworker may encounter. Due to its interlocking sections, it becomes strong and can cope with various forces, such as horizontal, vertical, lateral, and twisting.

However, it is unsuitable for drawer construction and other objects that move a lot. It does not matter how well the wood joint has been made and how strong it is. It will loosen over time due to the movement.

With the Stopped or Blind Mortise and Tenon Joint, you do not run the width of the mortise so that the wood joint can be seen. It stops halfway, disguising it to look neater and more visually appealing. That makes it ideal for furniture making, such as tables, chairs, and dressers. The overall look of the wood joint is much better, so you get the best of both worlds.

Advantages

- Versatility

- Strong

- Robust connection

- Durable

- Classic design

Disadvantages

- Intimidating to beginners

- Not suitable for thin material

Dowel Joints

The dowel joint is simple in woodwork in appearance and theory. Drill a few holes and insert a few pegs. Dowel joints can form strong joints without mechanical fasteners like nails and screws.

A dowel joint, or doweling, is a joint that connects two pieces of wood by drilling dowel holes in each piece and using a wooden peg which is the dowel to attach them. The dowels are a bridge between the two boards and hold things together. They also swell when covered with wood glue, locking the wood joint in place. They will not be messy since they are invisible once assembled.

Dowel joints are strong, and increase the glue surface. They also use each board’s long grain rather than the end grain at the end of a butt joint. The dowels are made from wood regardless of whether it is hand-carved or store-bought. They come in specific thicknesses. Fluted dowels have spiral indentations, and they swell more when they come in contact with the glue. There are plastic and metal dowels for adjustable shelving construction.

You are likely to see dowel joints in woodworking and cabinetmaking. The dowels better secure butt joints for cabinet doors or align two boards for a flat edge joint, such as a tabletop. They make drawers, picture frames, and other projects where glue alone might not be enough, but visible mechanical fasteners would derail the aesthetic. Dowel pins are popular in mortise and tenon joinery, although that is a different method altogether.

Using a doweling jig is the easiest method for making accurate dowel joints. These jigs come with sleeves, several holes for the appropriate dowel size, or fixed hole sizes. Choose a dowel around ⅓ of the board’s overall thickness for efficiency.

Dowels are structural reinforcements in cabinet making and other applications, including Furniture shelves, supports, moveable game pieces, and hangers. Use dowels when it is not allowed to use nails or screws for safety reasons.

Use a dowel joint when the wood is too thick to screw or nail, use a dowel joint. The joints made with wood glue are even stronger. The dowel joint makes connections where no nailheads or screw heads should be visible.

Advantages

- Dowel jointing is a fast process

- Neat finish

- There is no need for screws or nails

- Strong

- Solid

Disadvantages

- Not ideal for beginners

- Getting the alignment right can be difficult

Butt Joints

A butt joint is one of the simple methods of joining two pieces of wood together. Place the end of one piece on the surface area of another in a right-angle formation. Since it is the weakest type of wood joint, it is used in wall framing on construction sites and other simpler jobs. However, its strength depends on the kind of reinforcements used.

Butt joints are glued together. That is why mechanical fasteners, nails, and screws cannot be of additional durability. Add reinforcement to increase the joint strength, depending upon glue to hold the workpiece together.

A butt joint joins two pieces of material without any special shaping. As the name butt joint implies, it comes from the joined wood material. The butt joint is the simplest as it involves cutting the material to the appropriate length and putting them together. It is also the weakest because it relies upon glue or welding alone to hold it together. The orientation of the material presents only one end to a long glueing or welding surface. That is why the resulting wood joint is weak.

The butt joint is a simple joint to construct. Members are docked at the right angle and have a required length. One member will be shorter than the finished size by the thickness of the adjacent member. For enclosed constructions, such as four-sided frames or boxes, consider the thickness of the two adjacent members. That wood joint is easy to construct and provides a range of uses. A butt joint is strong enough for most applications.

Advantages

- Easy to assemble

- Fast

- Strong

- No need for special tools

- Quick to make

Disadvantages

- It is not elegant

- Difficult to align

Dovetail Joints

The Dovetail joint is a strong joint with tensile strength. It cannot be pulled apart and connects the sides of a drawer to the front. The wood joint is permanent when glued and requires no additional mechanical fasteners. It has a series of pins cut to extend from the end of one board interlock with a series of tails cut into the end of another board. These pins and tails have a trapezoidal shape.

Dovetail joints are strong by design and offer an attractive finish that is a true sign of craftsmanship. Professionally cut and glued dovetail joints are impossible to separate. Dovetail joints are cut by hand with a saw and chisel. The dovetailing machine is programmed with the exact drawer box height and style of dovetail for quick and efficient cuts of dovetails before the craftsman hand glues and finishes the drawer.

Dovetail joints have evenly spaced cut pins and tails. They have wide-cut pins and smaller tails. Standard cut pins and tails offer more strength in the drawer, although not so strong. A through dovetail joint works at the end grain of both boards. It is visible where the wood joint is assembled, creating a stunning dovetail from all sides of the box. This wood joint is strong and sometimes known as a lapped, English, or plain dovetail.

Half-blind dovetail joints are strong, economical, and attractive. In a half-blind joint, the end grain is not visible from the front end, tails are housed in sockets at the ends of the board forming the front of the drawer. These dovetail joints are only visible at the side of the drawer.

Advantages

- It is stronger

- It has a large glueing area

- It resists pulling

- Attractive

- It holds together even without glue

Disadvantages

- Difficult to mark out and cut

- If dovetail joints are poorly made, they will lose the advantage of strength and durability

Pocket Hole Joints

This wood joint is one of the most popular woodworking joints. Like a butt joint, it has pocket hole screws, but two drilling operations are required. It is there to counterbore the pocket hole, which takes the screw head contained by the piece. It also includes drilling the pilot hole with a centerline that must be the same as the pocket hole. This pilot hole allows the screw to pass through one piece to the adjoining piece.

You can use it to join two pieces of wood in any configuration. That is an end-to-edge, end-to-face, mitered. The uses of pocket hole joinery are unlimited. Assembling structural frames and cabinet face frames is also one of its applications.

Pocket holes work in building furniture, cabinets, decks, stairs, and other carpentry projects. This process is fast. Use the right tools on hand since pocket hole screws are quick and easy to install in any woodworking project. The angle of the pocket holes gives a strong bond between the two pieces of wood. They work on structural projects like stairs and decks.

Avoid splitting wood when drilling in screws since they come with self-drilling tips (Woodworkerlodge.com). Do not drill too close to the wood edge to create the strongest bond. Use only one clamp to keep the two boards together while drilling.

Avoid dry time for glue. Pocket hole joints are permanent, so do not use wood glue. That saves you time since you do not have to wait for pieces to dry before moving on to the next step.

Advantages

- Glue is unnecessary

- No gaps forming

- Requires only one hole to be drilled at a time

- It does not require any complex measurements

- Quick repairs

Disadvantages

- A broken pocket-hole joint likely cannot be repaired

- Not ideal for joining thin pieces of wood

Conclusion

There are several types of joints for different wood items. Choose the right wood joint for your project to avoid damage, mistakes and errors. Choosing the type of wood joint can be difficult for beginners, but in time they will master this skill. Each wood joint works differently on certain projects. Almost all projects have a specific type of wood joint. I assume you understand some tips on how to make wood joints.

FAQs

What is the strongest woodworking wood joint?

Mortise and tenon joint is the strongest woodworking joint as it holds well. It is well known for its strength, versatility, and simple design.

How do I know which wood joint to use for a specific project?

To better understand how different wood joints work, it’s worth trying a few to see how they perform. While some general guidelines exist for choosing joints for specific projects, there is no hard and fast rule. The best joint for a project will depend on several factors. These include the type of wood used, the size and shape of the pieces, the intended use of the finished product, and the desired aesthetic.

For instance, dovetail joints are commonly used for drawers, mortise, and tenon joints for chairs, and box joints for crates. However, it’s always recommended to experiment with different joints and gain hands-on experience to find the best joint for your project.

Can I use any wood for any joint?

Different types of wood have different properties, such as density, hardness, and grain. This can affect the strength and appearance of a joint. For example, some joints require harder or denser wood to connect strongly. Others require more flexible wood to prevent cracking or splitting.

Hardwoods such as oak, maple, and cherry are generally used for joinery because their dense and durable nature makes them sturdy joints. On the other hand, softwoods such as pine or spruce are generally used for simpler joints, as they are naturally more flexible.

To get the best results for your project, consider the type of wood when selecting joints. Always choose a wood suitable for the joint you intend to make to get the best results.

How do I properly execute a mortise and tenon joint?

A mortise and tenon joint involves cutting a rectangular slot (mortise) in one piece of wood and a corresponding tongue (tenon) in the other piece of wood that fits snugly into the mortise. To make this joint properly, you must accurately measure and mark the joint, cut the mortise and tenon to the correct size and shape, and assemble and secure the joint with glue or other fasteners.

Are there any wood joints that should be avoided?

While many types of wood joints can be used for various projects, some joints may be more difficult to execute or may not provide the strength needed for a particular project.

For example, butt joints, where two pieces of wood are butted together and fastened with nails or screws, are unsuitable for load-bearing structures or long-lasting projects because they offer little strength and can break apart over time.

Also, cookie joints, where an oval cookie is inserted and glued into matching slots in two pieces of wood, may not be the best choice for large or heavy projects because they are not as stable as other joint types such as slot and tenon or dovetail joints.

Choosing a joint that is appropriate for your project and provides the strength and durability you need is important. Some joints may be more difficult to make, but most joints can be made successfully with the right skills and tools.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024