Two of the most commonly confused devices are surface planers and thickness planers when it comes to woodworking. Even though they look similar and both have the task of shaping and calibrating wood, there are some important differences between the two that every professional should know. Below is a detailed overview and comparison of the two types of planers.

What is a Surface planer

A surface planer is a hand-held power tool used to create a smooth, level surface on a piece of wood. It does this by shaving off a thin layer of wood with rotating blades. Surface planers are ideal for smoothing warped or rough boards and for creating an even thickness across a piece of wood.

The Surface Planer is for planing one side and one face of solid timber straight and square to each other. It is well known in the woodworking industry for its accuracy. However, the accuracy depends on the squareness of your face edge and face side produced using this machine.

The machine is hand-fed by a single operator and has a range of sizes for all workshop needs. The surface planer can also be used for bevelling and chamfering with the help of additional jigs. A surface planer has two tables, an infeed table and an outfeed table. What separates the two tables is the cutter block set between them.

The infeed table is lower than the outfeed table for material removed when the timber passes over the cutter block. Surface planers use a range of cutter blocks, including a wedge bar hold system, centrifugal block, or spiral block.

Pros

- Accurate

- Adjustability

- Better surface finish

- Low maintenance cost

- High material removal rate.

Cons

- It is loud

- Need for additional jigs

What is a Thickness planer

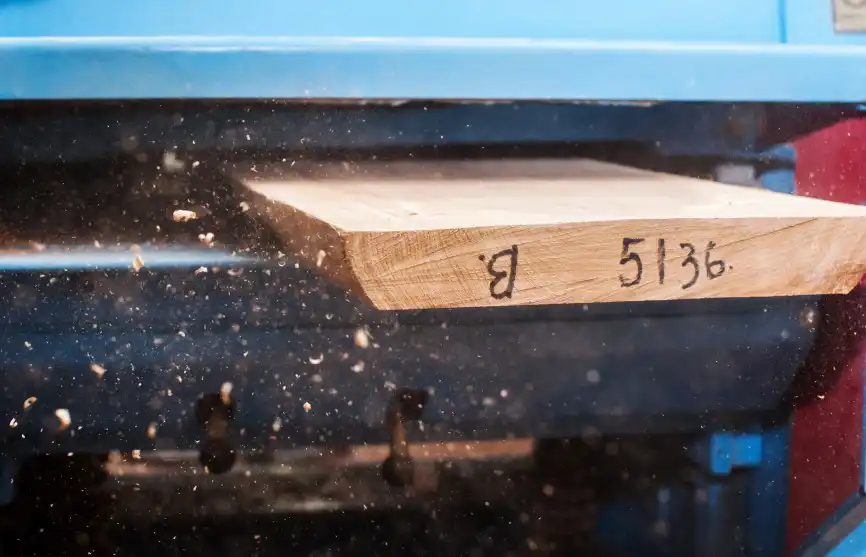

A thickness planer is used to create boards of even thickness. It does this by shaving off thin layers of wood until the desired thickness is achieved. Thickness planers are ideal for milling lumber to be used in woodworking projects and for creating thin strips of wood for veneering or inlay. The planing machine works on the desired thickness using the downside as a reference. The down surface has to be straight to make a straight board.

The first flat side requires face planing with a jointer or a planer and jointer sled. Unlike a surface planer or jointer, where the cutter headset into the bed surface, a thickness planer produces the first flat surface, especially in a single pass.

However, the thickness planer has more advantages since it produces a board with a consistent thickness, avoids a tapered board, makes passes on each side, and turns the board. It is for the initial preparation of an unplanned board.

A thickness planer serves three purposes that other tools do not. It makes the second face of a board parallel to the other face and smooths rough stock, thereby reducing stock down to the exact thickness you need.

Pros

- Consistency

- Adjustability

- Accuracy

- Portability

- The high material removal rate

Cons

- It makes splintered edges and pockmarked surfaces

- Cutter head misalignment

Favourite Features

Motor

The surface planer features a motor that rotates a cutting head since the machine is large and heavy. That is why it sits on a surface such as a plane bench or table. The surface planer size varies, and the size of the boards to be planed in the machine varies according to the machine’s size.

Industrial thickness planers accept wide boards and remove large amounts of material in a single pass. These machines have powerful motors which are of heavy construction. Recently, a range of portable thickness planers have become available which use affordable but noisy, universal motors rather than induction motors and are much less expensive than industrial versions.

Controls

When using a surface planer on a board, start with adjusting the planing machine so it cuts the board at the proper depth. That becomes a success by adjusting the controls on the planer. These can be manual control or electronic control for more accuracy.

The board is fed into the opening on one side of the machine and engaged by the in-feed roller, guiding the board deeper into the planer toward the cutting head.

The thickness machine has bed rollers for adjustments. Lay a straightedge on the rollers, and use a feeler gauge to check how far they stick above.

Cutterhead

The thickness planer has a cutter head that contains the cutting knives; a set of rollers that draw the board through the machine; and a table that is adjustable relative to the cutter head to control the final thickness of the board. Some portable thickness planers differ as the table is fixed and the cutter head/feed roller assembly is adjusted.

Table

The table is adjustable relative to the cutter head to control the resultant thickness of the board. Some portable thickness planers differ in the table fixed, and the cutter head/feed roller assembly is adjusted.

When using a thickness planer, adjust lower table rollers and the infeed/outfeed tables.

Knives

The surface planer uses knives for cutting. The knives remove material, and the outfeed roller pulls the board through, ejecting it from the machine at the end of the pass.

When using a thickness planer, start with setting the knives, so the tip is a 3mm projection from the cutter head. Zero the dial indicator on the cutter head. Move it over the blade at one end. Adjust the height of the planer blade to about 3mm as you lock it off. If it is a bit low, use the awl to lever it up a fraction.

What could be better: Surface Planer vs Thickness Planer

Surface planer

- There is a problem associated with the surface planer called snipe. It happens when the board is planed at a different thickness at the beginning or end of the planing process. The board is fed into the machine incorrectly. You can prevent that by feeding the board into the machine and supporting it as it leaves the machine, giving a clean plane down the course of the board.

- Another problem with a surface planer is the machine’s inability to make a straight cut if the opposite side of the board is not even or very close to even. If the opposite side is not even, the planer flattens the board by any imperfections on the opposite side.

Thickness planer

- It has to get rid of splintered edges and pockmarked surfaces.

- Cutter head alignment.

Similar Features

- They adjust the thickness of boards.

- Both planers flatten wood surfaces.

- Key Differences

- The thickness planer is bigger than a surface planer.

- The thickness planer focuses more on thickness, unlike the surface planer, which focuses on flatness.

The verdict

If you are going to mill and square up rough lumber and reduce the thickness of boards, you can use a surface planer. However, be ready to encounter the problem of sniping. Consider the surface planer when you want to plan one side and one face of solid timber straight and square. Its accuracy depends on the squareness of your face edge and face side produced using this machine. A thickness planer is there to maintain a certain thickness on boards. Since you have the necessary information on both tools, you may pick what you see working for you.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024