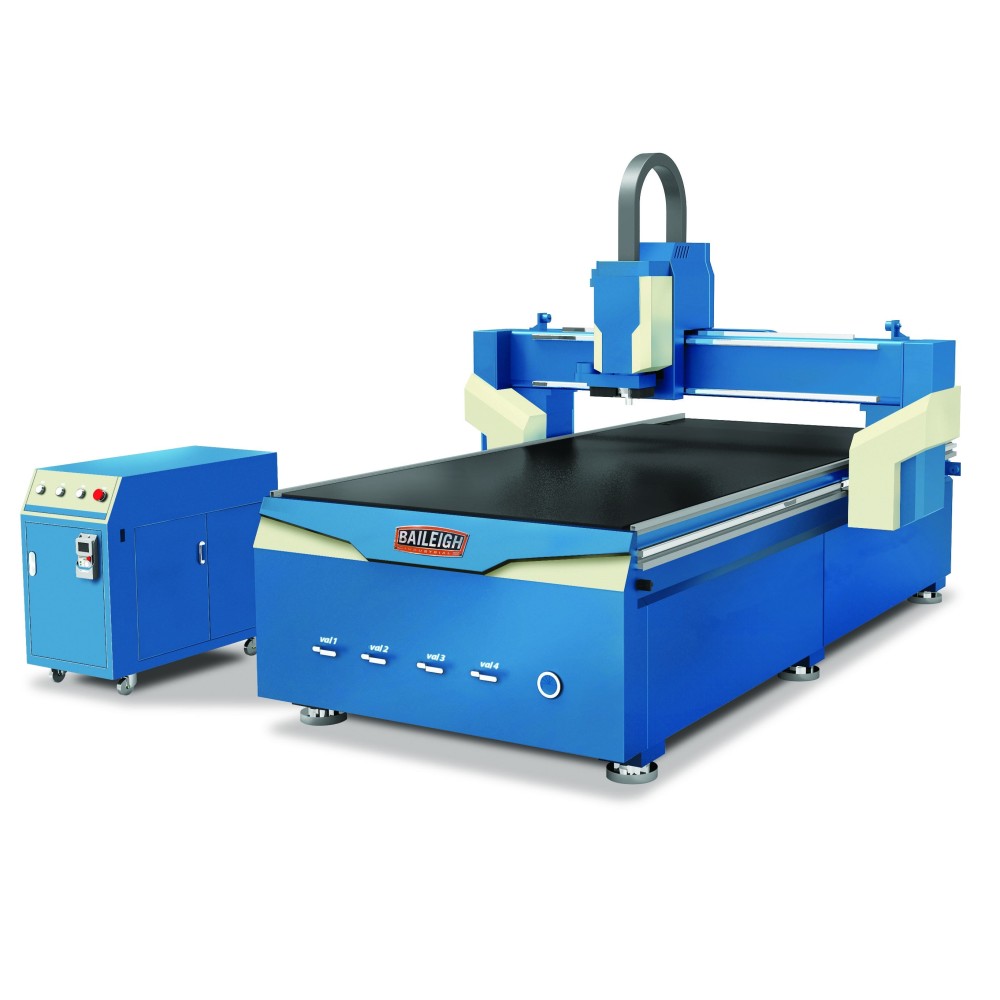

Baileigh WR-105V-ATC is a router table that comes with a correct alignment. It comes with software already installed. This CNC wood router table automatically changes tooling in 8 sec. You can program profile switches right into your design. This saves time and maintains precision during industrial production runs. It is an industrial router machine for heavy duties. A speed variance of 0 to 24000 makes it quick. The speed variance allows you to work on any material using the proper speed.

FEATURES

Set-up

The Baileigh WR-105V-ATC comes with correct alignment and no complications during the process. That makes it one of the best router tables for beginners. They do not struggle to assemble it. That reduces the working time. That way, you can push more volume in making items.

Software

The CNC wood router table comes with software for plotting out designs on your computer, turning them into cut patterns for the machine. There is a design software package alongside the cutting table. It takes just a few minutes to learn.

Control the X, Y, and Z axes using the integrated panel on the podium. The control panel is so easy, and even beginners do not struggle. Software provided with the system is a simple to use, CAD-based drawing and coding program. You create a new drawing or import files such as DXF, BMP, and JPG using the software.

Once created, the file is for the code needed to run the shape on the table. You may choose to enroll at a Technical College to gain more knowledge and experience. They might not have the same software as the table, but the techniques and functions are similar.

Power

The router machine runs on 220V 3 Phase Power, and servo motors ensure smooth running at fast and slow speeds. It works in most parts of the world. Before connecting the machine to the power source, make sure the power source is OFF. Before switching on the power, check the voltage and frequency of the plasma table power to see if they meet the requirement. The allowed range for the voltage is ±5%, and the frequency is ±1%.

Spindle

The powerful 12HP spindle tackles hard materials without flinching. It features a 9KW air-cooled spindle that stays accurate through years of production.

Speed variance

The speed variance allows users to work on any material. It uses proper speed, increasing performance and limiting mistakes. It gives you the chance to customize your items. Each material requires a certain speed for accuracy. The variable spindle speed is from 0 – 24000 Rpm.

Gantry

The high gantry is up and away from material, allowing you to see its operation. The y axis moves far enough for the gantry to clear the table. The gantry straddles the bed and carries the router spindle motion system. It is moved along the length of the bed by a precision rack and pinion system, controlled by the machine controller.

Collets

You are allowed to pre-load up to 6 collets with your chosen profiles. The router will switch between them as programmed.

SPECIFICATIONS

Weight

It weighs up to 3200lbs. That makes it a heavy machine for the industry. You cannot move it often as you work on products. Keep it stationary to make the operations bearable.

Cord

The Baileigh machine comes with a cord that allows you to plug the CNC machine from any power source. Keep your machine stationary as you move the cord only for power. That way, do not run out of power.

You cannot stop working because the battery is flat. The cord becomes useless.

Dust Collection

This machine has a dust collection port. Choose between a dust collector and a hose, although the dust collector comes with the table. The minimum required air volume of the machine is 750 m³/hr. The minimum required airspeed at the end of the flexible tube is 20 m/sec.

Use care and planning when attaching and routing flexible hoses for dust collection. Avoid creating an entanglement hazard or interference of the work station when routing the hose. The 4inch dust port is part of and on the top of the router head.

When connecting the flexible hose, plan for the hose to go with the router head when the machine is in operation. Put it where it does not interfere with the operator or the workpiece. Protect the hose from creating a trip or entanglement hazard. Secure the hose to the port to prevent accidental detachment during operation.

Bobcad-Cam Express Design Software

BobCAD-CAM helps you bring out your drafting artistry skills. Each new cutting table comes with one license of the latest version of BobCAD CAM Express software. You will get directed to the download links and the license activated. If you have no idea how to get started with the software, contact a representative from BobCAD-CAM.

Spindle Speed (RPM)

The router runs from 0-24000rpm. The routing speed and feed determine the surface finish, power requirements, and material removal rate. The material determines the feed rate. The tool material, the rigidity of the workpiece, the size and condition of the engraver, and the depth of cut when choosing speed. The maximum speed makes the process quick.

Table Length

The table is 152inches long. The higher the maximum workpiece height of a laser machine is, the higher the products you can engrave or mark with it. That is the distance between the working table and the focus point of the laser beam below the laser head. Measure the products that you wish to engrave or mark. Compare these dimensions with the table height. Consider the length and width of the working area. The higher the maximum height of the table if the engraver machine is, the higher the products you can engrave or mark with it. Choose a working table that is height-adjustable so that it covers a wide range of application possibilities. It comes with a laser table.

Verdict

If you are operating from an industrial setup, this machine can be perfect. Find a place for the machine not to move it often. You cannot move the machine alone due to weight. It is easy to operate and assemble.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024