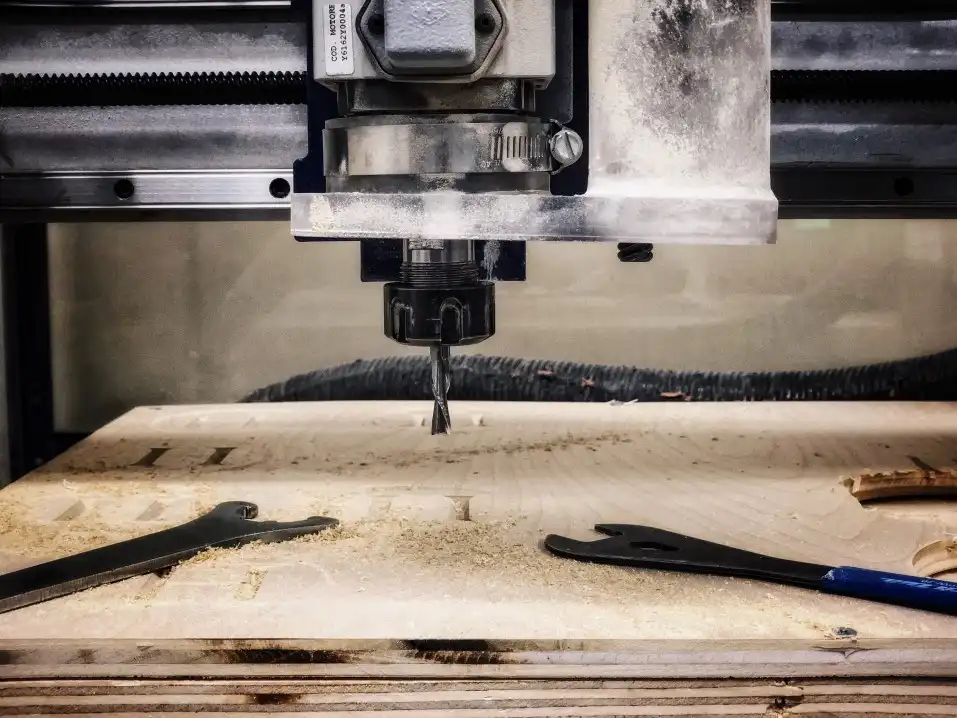

Can you use standard router bits in a CNC machine?

Yes, if the router bit removes wood quickly in a high-load situation. Many spiral router bits will work fine for woodworking tasks on the CNC machines. Although various router bits are used in a CNC machine, standard router bits still complete the task.

Can you use router bits in a milling machine?

Router bits are cutting tools with specific geometry for use on wood, plastics, nonferrous metals, and some composites. They offer high feed rates, depths of cut, and better finishes. Router bits work in CNC routers, machining centers, and milling machines.

Drill points are for producing clean cuts in aggressive milling applications. Some drill point bits are of composite material for increased tool performance. Square ends are for milling applications, including slotting, profiling, and plunge cutting.

Center-cutting router bits come with a straight flute and are used for standard milling applications. It works on milling metals or milling exotic materials, including Carbon Fiber Reinforced Plastic (CFRP).

Use carbide-tipped bits and a variable speed router to regulate the cutting speed when cutting aluminum with a wood router. You can machine aluminum with your router but be careful. Start by purchasing an end mill, since router bits are not for metal cutting. You can use end mills on wood and straight router bits since they are less expensive and more accurate.

Can you use metal CNC bits on wood?

You can use metal router bits to cut wood, plastics, and nonferrous metals. Sharp bits will give good quality cuts in any of these materials. Using a bit that has been cutting wood to cut plastic or aluminum, might not be a good idea.

Keep bits for plastic and aluminum separate, and avoid cutting wood with them. Wood is very abrasive and will dull bits faster than plastic and aluminum. You may go for a multi-purpose bit such as two-flute spiral bits since they cut a wide range of materials, including plastics, aluminum, foam, and wood.

How do I choose a CNC router bit?

When choosing a CNC router bit, consider the material you want to cut, the project, speed, and finish. I will explain these in detail below.

Project suitability

Know the project you are undertaking. Detailed work like lettering requires a V-bit. V-bits have a cutting profile in the shape of a ‘V’. They come with different angles that determine their purpose. A 60° V bit will give you smaller details compared to a 90° bit, which is well suited for larger or shallower details or letters.

Material compatibility

You need to know the material you are cutting to pick the ideal bit. The material matters so much that you will find different grades of carbides used for different materials. Going for the wrong bit will cost you efficiency and affects the bit or even the machine. Plastic requires a specific bit that will not melt it.

When new to CNC routing and you want a multi-purpose bit. Go for two-flute spiral bits since they cut a wide range of materials, including plastics, aluminum, foam, and wood. The 2-flute cutting spiral bit is an excellent all-purpose bit if you are still a beginner and do not want to buy 20 bits right away. The 60° V-bit is better for engraving, making signs, and cutting letters.

Speed

Speed and feed rate depend on the horsepower of the spindle. A high RPM results in a higher quality finish but results in higher friction that will increase the wear on your bit. That is why you need to refer to the spindle manufacturer’s speed parameters.

If you have to cut a large amount of material in a short time, pick a bit that can go through your material quickly. If you hate sanding hardwood, go for a bit that will leave a smooth finish. Higher tool RPM produces smaller chips, while higher feed rates produce larger chips. If the chips are too large, your bit will be likely to break, but if your chips are too small, you will be dulling your bit. It is all about getting the right balance.

Finish

Bits offer many cutting edges for extra flexibility. You have the option of going for 2-, 3-, or 4-flute bits. More flutes will give a finer quality of cut but go through your material much slower.

Can you use drill bits in a CNC router?

Yes, but do not use the drill bit for anything other than 1/8″ holes. On a CNC milling machine, you would use a canned drill program for each hole that involves pecking the bit.

How are router bits measured?

The length of a router bit is measured from the top of the shank to the bottom of the cutting edges.

How are CNC bits measured?

It is from the top of the cutting edge to the bottom. Whenever possible, use a cutter of a similar cutting edge length as the final depth of cut.

How do I use CNC engraving bits?

The bit removes material in a specific way. Routers use computers that determine the toolpath, and these routers require bits to make intricate cuts. The range of materials and designs cut by router bits has grown in diversity, and so have the types of CNC router bits.

The market is flooded with so many CNC router bits that picking the right bit for a project is not easy. Engraving is done with fine, point-shaped end bits at higher speeds. End Bits remove the material by biting it away with their flutes while spinning. Each end bit has a different amount of cutting flutes, depending on the diameter and the purpose.

CNC wood router bits manufacturer

Amana CNC Router Bits

Amana manufacturers offer long-lasting router bits that offer superior, smooth quality cuts. Consistency is what the company has managed to stick to. You are given a same-day Shipping service depending on your location (Source).

IndiaMart

IndiaMart offers a range of bits for different projects. You have categories to choose from and easier on your selection process (Source).

Woodsmith

Choosing the best router bits on Woodsmith requires a few things before buying. If you are a beginner, you need a lot of help before purchasing router bits. The shape, sizes, and purpose of the bits are factors to consider before purchasing a router bit. The manufacturer gives you a detailed guide to help you in the selection process.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024