What is a CNC Spindle

CNC spindle refers to the shaft at the center of the rotating axis of the machine tools. It is a rotary unit with a shaft, bearings, and attachments. Spindles rotate on the axis, which receives input on movement from the CNC controller.

The spindle controls the center part of a CNC machining. What determines the speed and cutting force of the CNC machine in the form of the spindle. A machine tool comes with several spindles, big one is called the main spindle.

The spindle comes with a diversity of configurations and options to meet the needs of different industries. Types of spindles are lathe spindle, milling machine spindle, grinding spindle, electric spindle, low-speed spindle, high-speed spindle, and many more.

Spindles are for metalworking and woodworking, electrical component creation, and manufacturing CNC parts with various shapes. CNC machine tool spindle drives the rotation axis of the workpiece or tool.

There is a relative motion between the cutting tool and the workpiece required in material removal. The spindle in CNC mainly provides constant power in a speed range to ensure sufficient cutting force.

The positioning makes the spindle stop at a position used for tool changing, boring tool withdrawing, and work requirements. The operation that comes with the servo shaft ensures the spindle rotates once, and the servo shaft moves a line. If there are multiple spindles in a system, two spindles can operate synchronously.

Types of Spindles

- Integral motor spindle

- Belt-driven spindle

What is a CNC router

A CNC router is a handheld router used for cutting multiple materials. It cuts through steel, wood, aluminum, plastic, and foam. It is similar to a CNC mill as they both use a computer numerical control to route tool paths that allow the machine to start performing the task.

CNC routers decrease waste and increase production. They are fast and come in different sizes. Industrial CNC routers are significant, and they use a large amount of space. However, there are desktop routers that use less space.

They are smaller, to the extent that they use a desk. The only disadvantage with the desktop router is that it is not as powerful as the industrial router. It is perfect for home use, and you connect it to your home computer. T uses the software on your computer and programs it to perform specific production functions.

CNC routers are used for woodwork, crafting different materials, and making art pieces. Woodworkers use CNC routers to cut and shape multiple pieces of wood. At some point, I had to use the router to design my rocking chair for the balcony.

The CAD and CAM software helps you control and operate your router. It easily cuts through maple wood for a project. You make cuts at the precise angles of your choice. You use bolts and screws to attach the pieces of wood as you make your item.

CNC routers are for manufacturing centers and homes. I advise you to go for kits that are easy to assemble if you are using the router for private projects at home. With time, innovative routers lessen the burden for you.

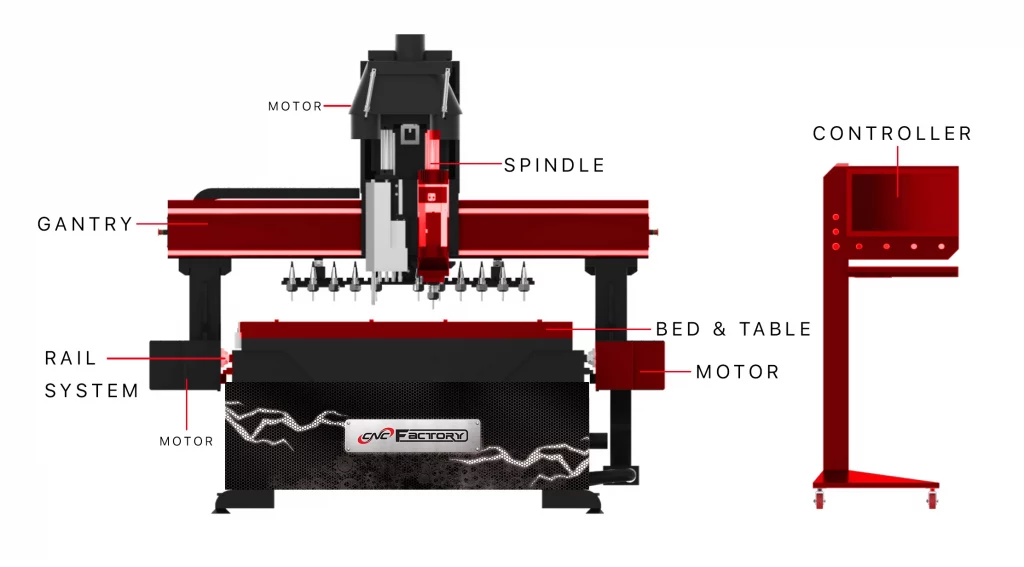

CNC Spindle motor

The spindle motor puts the router in a CNC router. It is mounted on a gantry. The spindle motor spins the cutting bit. You have a wide selection to choose from of the spindle motor. They come in different sizes and types, and they all meet different needs.

CNC router motor

Choose a motor for CNC that can provide you with the right torque and speed performance. Choose one based on your requirements. Sometimes you might sacrifice torque for speed or speed for torque. Avoid using a heavy stepper motor if the rest of your CNC components are not rigid enough to transfer the large force.

CNC router head

The router head cut the same pattern on a different project using spindles. That increases the machining speed and completes the work efficiency of multiple devices.

Sometimes the machining volume is not large, and a single spindle can also work and control the production cost. When batch processing, the product consistency is good, and the quality is high. One machine is made multi-purpose, economical, and affordable.

500W Spindle VS Router

The powerful 500w spindle motor opens up a wide range of materials you can use for this machine. The router is more powerful than a 500-watt spindle. It is also quiet for a router, but that changes when the endmill starts cutting, just like it does for a spindle.

800W Spindle VS Router

The 800w spindle is heavy for the standard CNC machine. Adding a water cooling system takes time and is complicated but worth it once installed. Using a router is hassle-free and quick.

CNC Spindle VS Router Comparison

Overall Power

A splinter is more potent than a router since it comes in heavy machines for heavy materials. However, that cost ease of use and affordability to the user.

Durability

Routers use brush-type motors that make them noisy, while spindles use brushless motors that make them quiet, reduce their maintenance cycle and make them durable than routers.

Cost

Routers are more affordable than spindles. Desktop CNC routers range from $1,500 to 5,000. Standard routers range from $5,000 to 30,000, and high-end routers range up to $100,000. It is now a matter of your needs and your budget.

Noise Levels

A router runs louder than a spindle due to turning the motor. The spindle is quiet because it drives with a high frequency. You can plug the router directly into the wall.

Accuracy

Routers have more runout than spindles and affect the cutting accuracy of workpieces. New routers have run out of 0.0010″ – 0.0015″, which degrade the conditions of router bit bearings.

Power Supply

A spindle is more equipped for high-power usage compared to a router.

Ease of Use

A router is easier to operate than a spindle. A spindle features more accessories and CNC parts, modified to keep heavy machining.

Cooling

Routers are air-cooled, whereas spindles are water-cooled, and you need pump tube water. The water cooling method uses water circulation to cool the spindle. The heat dissipation of a water-cooled spindle is much better than air cooling.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024