Once polished out well, you will find out that the machine can affect the discoloration of the natural wood. Lasers tend to leave a telltale imprint in timber. It requires close attention because it produces heat. This causes some burn marks along the periphery of the synthesized object.

It is necessary to understand that the burnt areas of your thing don’t mean the flame. Instead, it denotes the edges’ darkened parts from controlled engraving machinery. Typical observations from objects made out of laser engraving tend to exhibit an uneven texture marred with a dark color.

Consider the type and extent of depth you need when using a laser. There are only two depths permissible when using a lesser, and these are to engrave and cut through as recommended. Should you opt to cut through several layers in your project, make sure that you use the lesser to cut the layers individually.

For this reason, a laser to create multi-depth cuts is difficult, if not impossible, to achieve. You need to cut through several layers that you can engrave and cut neatly to set up a multi-layered map showing streets and topography.

Being an incredible machine as it is. A laser can give your objects an implausible detail and accuracy and at the same time minimize material loss. The shortcomings of using a laser’s engraving and cutting by heat are that it works best on thin layers of wood. A classic example of a thin piece of timber nicely cut by a laser is a pair of coasters.

CNC engraving is different from how laser engraving operates. It uses a rotating cutter head to separate the wanted object, a large piece of wood, and the trash. In contrast to how a laser does the engraving process. It can be drawn that you don’t experience discoloration of your object’s edges or face from using CNC.

Moreover, CNC engraving can provide a multi-dimensional cutting on your things. This is due to the supported ability to control the depth of the cut. CNCing the wood gives room for you to work on thicker pieces of wood instead of thin slices that are apt for lasers.

As such, laser engraving provides users with a pathway to get more detail and sharper edges. This is better than removing material by spinning the cutter head.

Lastly, you need to ensure that laser cuts and CNC are kept and used differently and appropriately. For example, the former produces interlocking pieces that are snugly and summed up into lines to create a puzzle or a pair of coasters. Whereas in the case of using a CNC machine, it becomes tiresome if not tedious as you have to cut the pieces individually to fit the desired measure.

Features and Characteristics of Laser and CNC engraving

Laser Engraving

- Laser engraving makes the deep depth and intaglio wood carving.

- Carved wood tends not to be rough but relatively smooth.

- Used in industrial sites when processing wood.

- Used for cutting acrylic carving crystal characters, among other processes.

- The coloring process encompasses word carving and a burning sensation.

CNC engraving

- CNC engraving is a combination of CNC technologies and engraving technologies.

- The CNC system is at the heart of making the corresponding processing sequence code.

- Reckoned for its high level of accuracy and high precision carving.

- Automation is at par compared to laser engraving.

- More industrial industries prefer the use of CNC woodworking engraving machines.

- Can handle paint-free doors, panel furniture solid wood doors, among others.

- Automation reduces manual labor and, as such, increases standardization, accuracy, and fast (speedy).

- It is difficult to engrave and cut points in a cheap way.

Laser engraving Pros

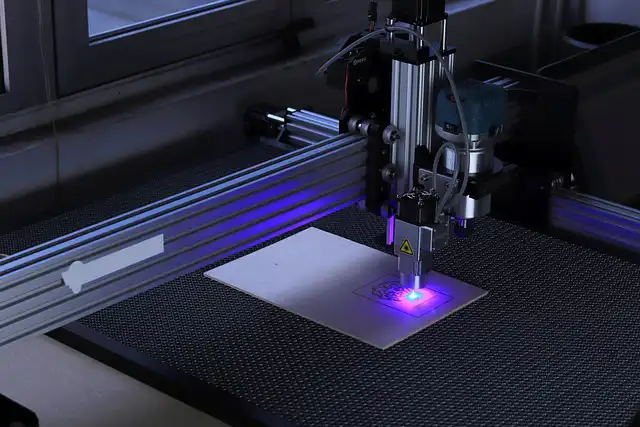

As alluded to earlier, laser engraving denotes the use of a laser beam attached to a machine or freehanded to cut designs as per your targeted object. The laser creates detailed images or patterns to meet your project demands as per your requirement in its operations.

- The use of the laser machines eliminates human error as it does all the set tasks, unlike the case when using manual hand engraving.

- It’s possible to make more intricate and detailed designs that are more crispy and cleaner.

- Laser engraving is easy and affordable today compared to traditional hand engraving.

- It’s easy to reproduce the exact design repeatedly; for instance, you can design a logo multiple times without variations. As such, it’s excellent and supersedes beyond simply using the hand engraving method.

Laser engraving Cons

- It requires prior experience in detailed designs. This can be a barrier to users who lack the artistic and technical ability to do expected works.

- Users must be proficient with vector graphic editors or designing software. These include Illustrator, Ink Scape, Corel draw, or Sketch.

CNC engraving Pros

- CNC machinery involves automation due to the embedded CNC system that permits it to operate unattended. As the user, you can find something else to do during the machining cycle. Automation increases precision and reduces manual labor.

- Unlike hand engraving, automation also reduces errors, operator fatigue. The precision of standardized time is required to finish multiple objects.

- CNC engraving consists of high consistency and accuracy of the workpiece. A verified CNC machine operating well can make thousands of identical parts hinged on accuracy and texture.

- Efficiency goes beyond conventional methods. Only the NC program needs to be adjusted when changing the design for the product/object of choice. Programming makes it possible to make products that are tricky to produce using conventional means.

Cons of CNC engraving

- Maintenance and technical operations require an advanced level of knowledge. Unlike that necessary to operate traditional hand engraving.

- Purchasing CNC machinery is expensive and requires a certain level of commitment.

- Pyrography Techniques for Beginners: Textures and Shading - January 23, 2024

- Troubleshooting Jointer Issues: Why is Your Jointer Not Flattening Wood? - October 11, 2023

- Unlocking the Secrets of Jointing to Increase Width - September 29, 2023