CNC Machines are used for Cutting

CNC machines cut materials across industries and applications for at-home hobbyists and large-scale production shops. CNC machining processes require multiple tools to make the desired cuts as drill bits. Drill bits are siCNC machine that combines tools into units or cells from which the machine can draw.

A lathe is a CNC machine that cuts workpieces as they rotate. CNC lathes can make precise cuts quickly by using multiple tools, and these are effective and precise as they offer; compared to manual lathes, they have fewer axes than CNC milling machines and are smaller in size. They are also more compact.

A CNC router is a machine similar to a hand-held router that cuts various materials. The CNC machine helps cut steel, wood, aluminum, composites, plastic, and foam.

It is similar to a CNC mill, and the machine uses computer numerical control to route tool paths that allow the machine to function. CNC routers reduce waste and increase productivity by producing various items more quickly than other machines.

A CNC electric discharge machine cuts material and makes shapes using electrical sparks. The material is removed from a workpiece by recurring electrical discharges between two electrodes.

These are separated by a dielectric fluid, which receives an electric voltage. The material is in between two electrodes, and it calculates the amount of electrical discharge each electrode needs to produce.

A CNC mill utilizes computer controls to cut different materials and translates specific numbers and letters to move the spindle in various ways. Mills use G-code, a standardized programming language recognized by most CNC machines.

A CNC mill has multiple functions, such as face milling, shoulder milling, tapping, drilling, and turning. They come in three to six-axis configurations, and it is the largest machine compared to other tools. That makes it a high-end machine amongst others.

CNC Machines can be used for Engraving

CNC machines are also for engraving items. Make use of a laser or a rotating tool in a milling machine. Lasers engrave in two ways. They cut material and are not powerful enough to cut the material, it discolors it in a visually distinctive way using a process called Laser marking.

Laser engravers are simpler than machines that use rotating cutters. The laser beam imports no force to the workpiece, and work holding is not an issue. The workpiece rests on the laser machine’s table without anything supporting it.

CNC Machines can be used for Routing

A CNC router can be used to make door carvings, interior, and exterior decorations, wood panels, signboards, wooden frames, moldings, musical instruments, furniture. They see use in industry in the thermoforming of plastics by automating the trimming process.

Some CNC uses my Bosch or Dewalt routers. CNC routers help you carve wood, cut out materials, engrave objects, and a lot more. Long back, routers were huge and not affordable, but now there are multiple entry-level, desktop CNC router systems for hobbyists and beginners. Laser cutting and laser engraving machines have cutting guides that assist you.

Can be used to carve wood

CNC routers cut almost all materials such as wood. CNC mills also cut both soft and hardwood. A CNC machine makes your woodworking production process smooth and allows you to make things you would find difficult to do manually with any power tool.

There are many excellent CNC routers available. The ideal machine for a woodworking application varies depending on your experience. You can be a hobbyist or not do some serious production work.

Can be used to make signs

A CNC router makes unique, intricate, and visually appealing signs hard to achieve with traditional methods. CNC routers make digital cutting, routing, and finishing through a visual registration system. Omni Channel’s CNC routers are one of the best models that deliver high precision, a prerequisite for sign making.

ShopSabre CNC routers also give full-production manufacturers in the sign and carving industries. It does not matter if you work with foam, wood, plastic, acrylic, aluminum, brass, or other materials.

There is always a ShopSabre CNC router that fits your sign-making and carving needs. When choosing the best option, look for advanced features such as vision recognition systems, ADA signage capabilities, tangential knife systems, or multiple tool capabilities. There is an option for any level sign shop.

CNC routers make a simple design on 2D projects and even more complex 3D signs or carving. ShopSabre delivers the result you want, and the above features for a CNC router help by allowing shops and manufacturers to produce better signs and carvings for less.

It can be used to engrave names on jewelry

In jewelry manufacturing, a CNC tool is for producing jewelry designs. There are two types of jewelry engraving machines: manual and computer-numeric-controlled (CNC). Manual machines require the operator to use a hand tool to control the engraving process and are used for basic designs that don’t need as much precision.

Computers control CNC machines, which allows for more intricate designs. These are faster and more accurate than manual machines. CNC engraving machines come in a variety of sizes and with various features. Three-axis (3-axis) machines move the jewelry up and down, left-to-right, forward, and backward. A 5-axis machine can move the jewelry in all directions, making more complex designs.

Can be used to smooth the edges of the wood

It is important to note that cutting material alone is not enough. The edges have to be smooth. A cutter may work well with one type of material but might not always be the best choice for others. Cutters cut materials, making them last longer and perform more effectively than standard cutters.

The issue when using a cutter to cut the material lies in the quality of the edge cut. There are many applications where that edge will be, hence the need to achieve a smooth, clean and shiny edge, unlike the untidy and rough.

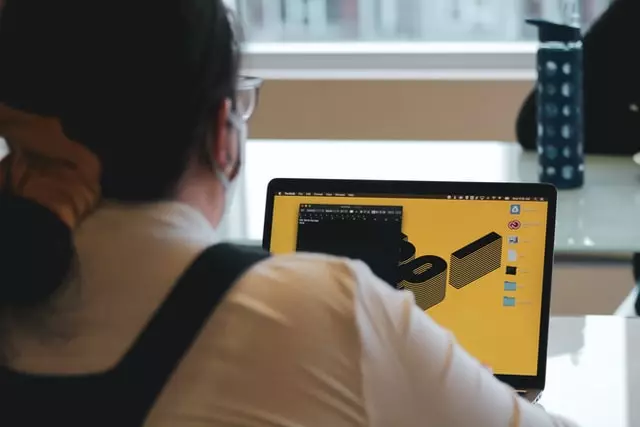

3D printing

There are CNC machines for 3D Printing and hybrid machines for cutting, routing, and 3D printing. A 3-in-1 3D printer is a rare tool, and few manufacturers still try mastering several tool processes.

Fewer users manage to combine them into one simple-to-use package. There has been a spread of machines in all shapes and sizes. These range from small and personal projects for the home to bigger ones. Full-on productivity platforms are for professional usage. Snapmaker 2.0 A350T) is for 3D printing, CNC carving, cutting, Laser engraving, and cutting (See Price of the Snapmaker 2.0).

Cutting metal

A CNC router machine still cuts aluminum, copper, and other soft metals as much as it cuts acrylic board, wood materials, plastics, plywood, and other materials. CNC router metal processing is one of the economical ways to cut metal and achieve multiple material processing.

The CNC router machine is suitable for fast and heavy cutting of soft metals. There should be a balance of depth per pass, feed rate, the correct end mill, and cooling. You can still cut metals without cooling.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024