The abbreviation CNC stands for Computer Numerical Control. A CNC machine is a programmable device that can autonomously perform the operations of CNC machining. CNC machinery uses computerized controls and machine tools to remove excess material from a workpiece. It can be wood, metal, plastic, or aluminum.

The result is a custom-designed product. CNC machinery is prevalent in many industries. Common uses include the machining of parts and prototypes for telecommunications, aerospace, medical industries, etc.

The CNC machinists read the CAD and CAM files and blueprints. It works with commands fed by the programmer to start a task. The machine then listens to the instructions and moves parts onto the workpiece to perform as requested.

What does a CNC machine do?

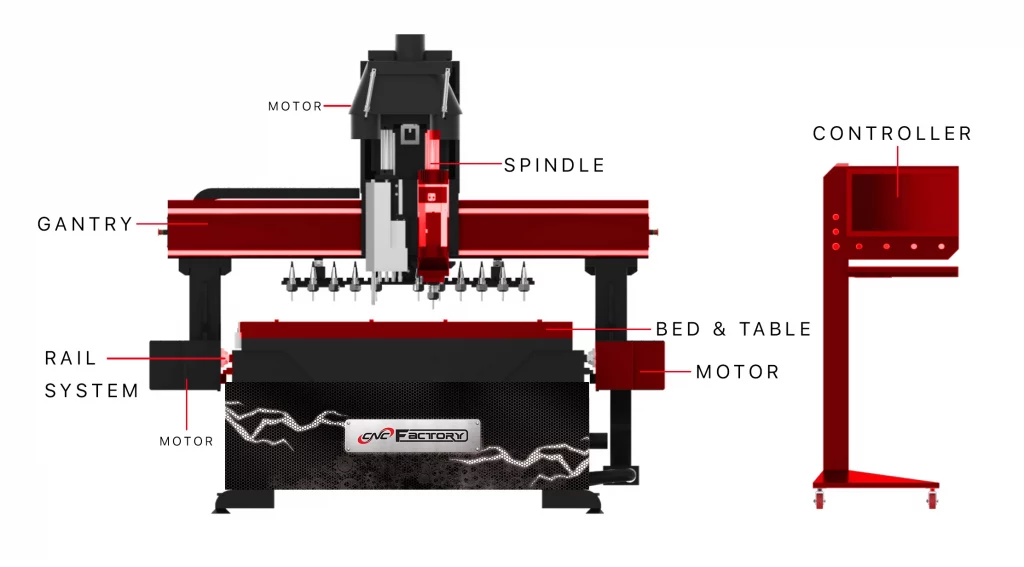

Generally, the CNC machining process requires multiple tools to produce the desired cuts. It involves combining tools that form typical cells to come up with the best designs. General CNC machines move in one or two axes, and the advanced have extra axes. These advanced CNC machines can flip parts over automatically. This enables users to remove excess material that was previously underneath.

A CNC machine uses Computer-Aided Manufacturing or Computer-Aided Design CAD software instructions. These softwares are programmed using G code which the controller can read. The computer program fed into the controller reads the design specifications. It moves the cutting tools onto the workpiece to perform as instructed.

What is CNC Fabrication?

CNC fabrication uses CNC Machines and programming codes to construct products from raw materials. Preprogrammed software controls the movement of the CNC machine’s production equipment. It produces workpiece designs from natural materials such as metal and wood.

What is a CNC LATHE?

CNC lathe involves using a CNC lathe machine for manufacturing or designing parts. The device is provided with Computer Numerical Control systems. It is supplied with design instructions to perform as programmed while the material is clamped and rotated by the main spindle. The cutting tool operates while mounted or tied in various axes. The workpiece is cut in a circular direction with indexable tools. CNC lathe machines are ideal for complex designs that aren’t workable with manually run machines.

CNC lathe machines come in different configurations: horizontal, Vertical, Slant bed, Standard, flatbed, etc.

Generally, a CNC lathe operates on 2-axis with the tool located in a fixed position at an 8 to 24 station turret. Some CNC Lathes machines are called CNC Turning machines because of the rotating action of the part. Other lathes machines with extra options such as Y-axis or sub-spindles are turning centers. The following are some of the standard components found on lathe machines:

- The Spindle

The spindle is the core of the CNC lathe tool, consisting of a spindle assembly and a spindle drive system. Some of the moving elements of the CNC machining include motors, the chuck, and gears. The C-axis helps position the material assembled with the spindle. You can find tool holders installed at the turret disk.

- The Chuck

The chuck’s primary purpose is to grip the workpiece that requires machining. The main spindle holds the chuck and rotates both the workpiece and the chuck.

- Headstock

The headstock holds the central spindle and comprises the main motor. When choosing a CNC lathe machine, always look for one that can handle high torque at low speed, ensuring high performance.

- Tailstock

The tailstock provides an extra support force to the end of a component necessary for long and extra-long workpiece machining.

- Tool Turret

The turret mounted on the tool turret offers the changing of cutting tools required for machining. The number and size of the devices mounted on the turret determine its size.

You can use a CNC lathe machine to produce precise round shapes with an Inner Diameter and an Outer Diameter. CNC lathe machines are common in automotive, oil and gas, aerospace, electronics, mining, power plant, oil, and gas. Some CNC lathe machines come with tools to work on multiple axes, especially modern ones.

CNC lathes are so beneficial they do not require highly skilled operators. They are fully automated, which allows more accessible and quicker production. CNC lathe machines are also highly versatile. They allow the design of all kinds of products and parts; they can also produce 99.99% accuracy and are cost-efficient. You can also machine cylindrical parts while holding tight tolerances with CNC lathes.

What is a CNC cutter?

A CNC cutter is a CNC device that can cut sheet metals, metal arts, metal tubes and pipes. Generally, its purpose is to cut off the edge of the workpiece. After all the software programming is done, the cutter removes the excess materials from the workpiece as instructed.

Advantages of a CNC machine

- CNC machines have a lot of benefits, and these include:

- You can use CNC machines 24 hours a day without 365 days a year. You can only switch them off for servicing or occasional maintenance, guaranteeing you a high production level.

- You can update your CNC machine by upgrading the softwares used to drive the machines.

- CNC machines have programmed designs that can be manufactured many times without changing the products.

- You can operate a CNC machine even if you do not have many skills. There are also beginner CNC machines that are helpful for CNC starters.

- CNC machines can be left to work on their own. They require minimum supervision, and one person can supervise many CNC machines. The cutting tools need replacing occasionally.

- CNC machines increase production speed and efficiency. They allow manufacturers to work faster and deliver high-standard products.

- You can safely operate a CNC machine because the machining process will all be automated. It won’t be necessary for operators to be anywhere near the cutting tools. This has decreased occupational health and safety accidents.

Companies have benefited a lot from these CNC machines in production and accuracy.

- Pyrography Techniques for Beginners: Textures and Shading - January 23, 2024

- Troubleshooting Jointer Issues: Why is Your Jointer Not Flattening Wood? - October 11, 2023

- Unlocking the Secrets of Jointing to Increase Width - September 29, 2023