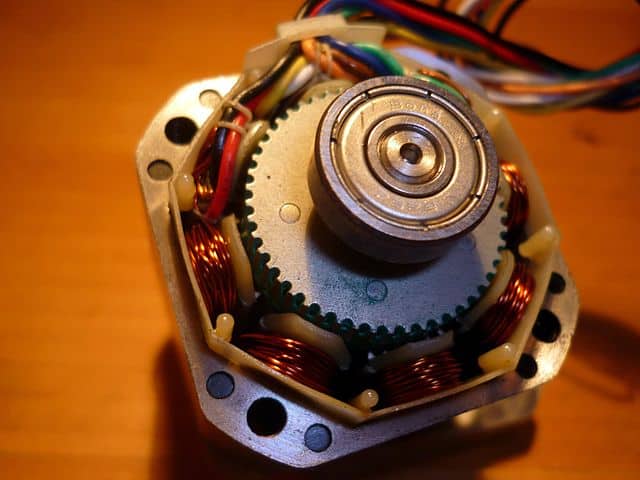

Choosing a stepper motor for a CNC router is a bit tricky, especially if you have just started with CNC routers. A CNC stepper motor converts electrical pulses into mechanical movement. It usually comes with a spindle that rotates 200 steps per revolution in discrete increments.

CNC stepper motors are helpful in areas where controlling movement is a norm, especially governing position, speed, and synchronism. You have to note a few things to get the best stepper motor size suitable for your needs and specifications.

CNC stepper motors are primarily standard in industries that use engraving machines, pick place devices, X-Y tables, etc. The stepper motors come in varying sizes, including NEMA sizes 11-57, with NEMA 23 being the popular one used in hobbyist CNC machines. Smaller stepper motor sizes range below NEMA 17 are helpful in the animatronic and robotic industries, while larger ones are essentially helpful in larger CNC machines.

How to size a stepper motor

Knowing the correct stepper motor size involves current and voltage needs, load requirement, torque, and voltage. With many stepper motors in the market, getting the right size is tricky and confusing. However, this article can assist you in deciding the correct one for you at the end.

- Evaluating the current and voltage requirements

Handling a wide range of current is a technique that your machine should have to test different levels of the system’s voltage that best fits your application. The current and voltage need maximum step pulse rate, and micro-stepping of a stepper motor is essential when you want to select the correct size. To guarantee the smoothest possible motion, make sure you choose a driver with many step resolutions to test for different microstepping settings. A typical stepper driver should produce at least 1.4 times the rated current on the stepper motor.

- Ascertain the load requirement

Ascertain the load requirement between frictional and inertial load is a normal thing that you should always do. Use a transmission connecting motor torque to the load torque if you need pure inertia. Remember that you also require a machine that measures the force required to have the load move at the required speed and acceleration. Always measure the rotary pressure using a torque watch for simplicity.

Moreover, you should ascertain the use of the supply voltage. The reason for doing this is to select a stepper motor that integrates a minimum of twice as much torque as is required to achieve the needed operating speed. Make use of a stepper motor with a rate of approximately 1/4 that of the supply voltage. Finally, to get the number that will help you choose a stepper driver, look at the needed driver current to select the desired motor torque.

- Torque issues

Problems related to torque are most common in stepper motors. The inertia mismatch between the load and motor causes the stepper motors not to accelerate fast enough. It’s either the inertia mismatches or not enough torque speed.

The solution is to find a motor size that matches the size of the load. You wouldn’t want your CNC router system to reverberate and produce jittery motion or loud noise because of a lot of torque produced by the stepper motor. So always take note of these torque issues to get the best size stepper motor.

Always apply the correct voltage size to the chopper drive. Micro stepping will assist in increasing the resolution of the system, thus preventing the wrong sounds and vibration.

If you choose an undersized stepper motor for your CNC router, the result is excessive heat and improper acceleration. On the other hand, an oversized will result in the stepper motor producing higher RFI/ EMI and even running louder.

If you consider all this information, you have seen that you won’t go wrong choosing the correct stepper motor size for your CNC router.

- NEMA 23 stepper motor

A NEMA 23 stepper motor consists of a 2.3×2.3 inch faceplate. You can drive it at the desired speed without losing a single plate when using it in low-speed applications. It is ideal for CNC machines, 3D printers, and robot arms. The NEMA 23 has a different torque, with the maximum torque measuring 3Nm.

The NEMA 23 ranges from $23.99 on Amazon, and if you want to ship, it will increase depending on your location.

STEPPERONLINE Nema 23 CNC Stepper Motor

- Dual shaft closed loop stepper motor.

A dual-shaft closed stepper motor has a shaft coming out of the face and rear of the engine. It is ideal when closed-loop speed monitoring is essential in your application. It can also give servo motors and position feedback to correct and detect positioning errors.

Best CNC stepper motor driver for CNC

We always want the best when it comes to choices. Many stepper motor drivers work according to the customer specifications and the type of CNC router. A CNC stepper motor driver works as an actuator that transforms pulse signals into angular displacement signals. The performance of a stepper system also depends on the stepper driver. The following are some of the best CNC stepper motor drivers.

- Stepper Online DM542T

- BIQU- A4988 stepper driver

- SongHe DRV8825 stepper driver

- GECKO G540 stepper driver

- StepperOnline DM860T stepper driver

CNC stepper motor selection

Here are a few steps that you should consider when choosing a CNC stepper motor for your CNC are

- Make sure it has the same linear drive components for each axis.

- The size of the machine should be the same, that is, with a similar footprint and work area.

- Make sure the weight of the spindle is the same.

- The gantries of the motor should be of the same weight as the gantries of your structure.

Above all, if you can answer the following questions, you can choose the right stepper more for your CNC.

- What is the level of accuracy needed when aligning the load?

- What is the amount of torque you require to move the load?

- How quickly does the load have to be transported or accelerated?

- How is the motor going to be coupled to the load?

HOWEVER, a CNC machine requires NEMA 17-23 stepper motor sizes. These can deliver.

Disadvantages of a stepper motor

- Stepper motor has very low efficiency.

- It does not make use of the feedback loop.

- Stepper motors produce a lot of noise.

- It is not simple to operate at high speeds.

If the motor is not adequately controlled, resonance occurs

How long do stepper motors last

Stepper motors can last depending on how you use them and the type of work. When offered proper care and maintenance, they can stretch for long. Generally, a stepper motor can stretch up to 10000 operating hours, which is close to 5 years, mainly on an eight-hour shift per day. However, it all depends on the type of your application you use them for.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024