Choosing between a belt sander vs belt grinder is an exercise that requires knowing what each tool offers. Consider how size, speed, power, function, and design differences between the two. It takes time to match features to your preferences for the best pick. Below is a review of both tools that will take you through the journey.

What is a belt sander?

A belt sander is a handheld belt sander or tabletop belt sander that features a powerful motor. The 10 amp motor works on heavy projects, and the belt sander has a large belt or strap set in a loop.

The belt moves in one continuous motion, moving in a circle at high speeds. It runs up to 3,000 surface feet per minute. The belt has sandpaper designed to remove small amounts of wood, even surfaces, paint, varnish, and smooth surfaces.

Belt sanders are for smoothing and evening things out because they can handle sandpaper of very coarse grit. They sand both width and against the grain. That is how you get a high rate of wood removal.

Belt sanders create a much bigger mess. The coarse texture of the belt removes wood quickly and gives you an even finish. If you want to strip away coatings or make a surface smoother, use a belt sander. The belt sander machine stock is flat and has specific thicknesses (Edusites).

Pros

- Durability and high-grade engineering

- Ergonomically designed

- Velocity control technology

- Ease of changing sanding pads

- Optimal efficiency

- Compatible with most wide paper grits.

- Sound level reduction

- Adjustable dust bag

Cons

- Not affordable

- No variable speed management

What is a belt grinder?

Belt grinders work in industrial facilities to grind down materials. They smooth the metals’ surfaces, and these machines work near the end of the metal processing process. A concave finish is achieved by belt grinding a metal object.

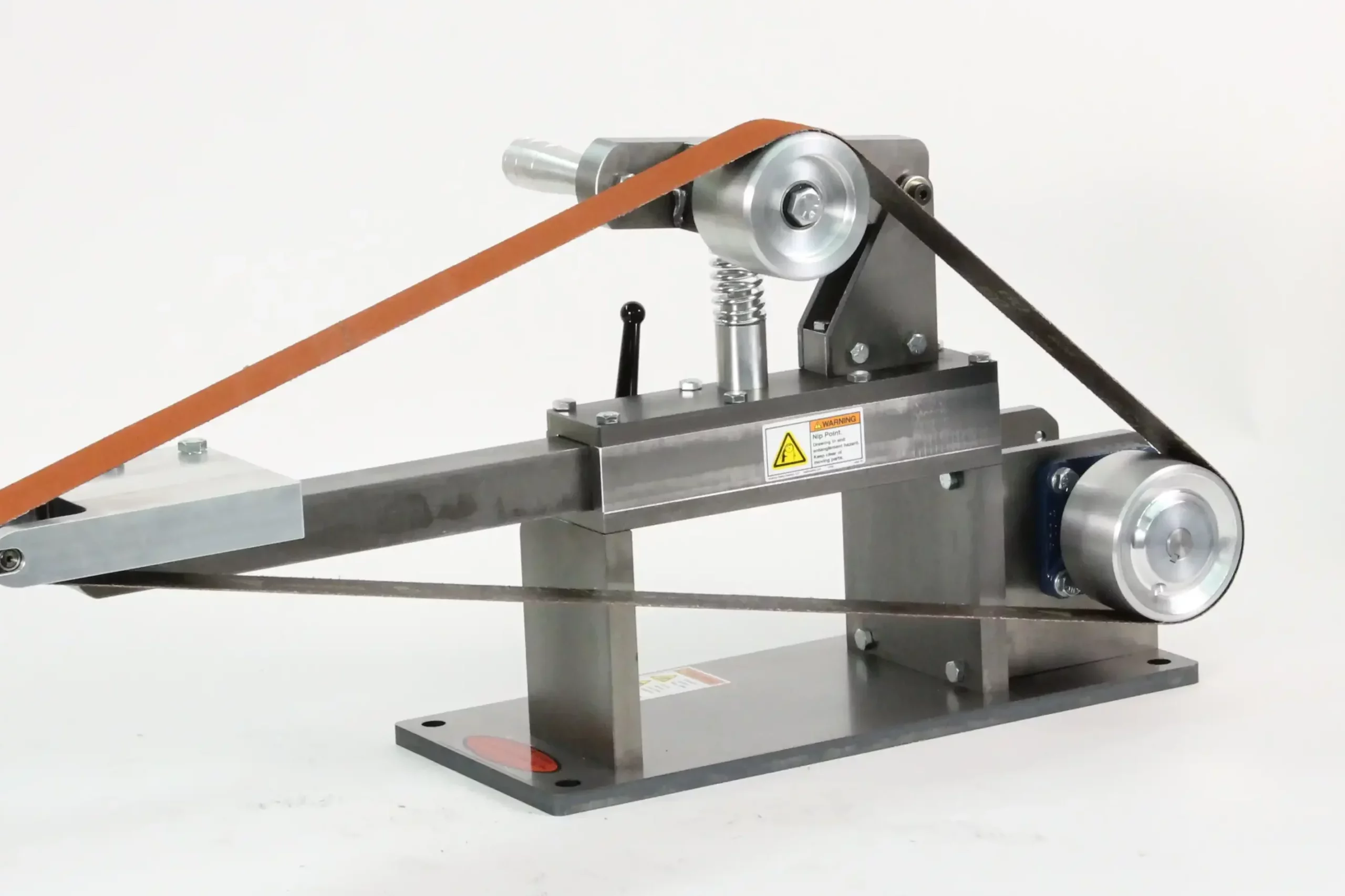

A belt grinder has an engine, two wheels on each side, and an abrasive metal-coated belt. The structure is small enough that metalworkers may operate it while sitting at a desk or bench. That is why belt grinders are also known as bench grinders.

A belt sander comes in sizes, and a belt sander is on a bench. Move the sander onto the bench-mounted material or the material on the sander belt. To sand the material, install the bench senders on the desk. The stationary belt sanders have disc sanders.

Belt grinders are for grinding metals to create the finish. Place the workpiece against a spinning strap covered with rough metals. The process helps make surfaces clean and gives the metal a unique finish.

Pros

- Portable

- Requires less pressure

- Fast

- Ease of use

- It gives shape

- Great quality

- Constant speed

- Less heat

Cons

- Not affordable

- Light grinding pressure

Features

Drums

The belt sander has two cylindrical drums around which a closed loop of abrasive paper travels. An electric motor drives the drum. The other is spring-loaded to maintain tension on the belt.

Dust collection system

Belt sanders on the market have built-in dust collectors. There is a handy feature in a belt sander that generates more dust. A belt sander can fill the air in your shop with fine dust in seconds. The small bags included with belt sanders only trap some of the dust. It pays to look for a sander with a dust port or an adapter that will fit your vacuum or dust collector.

Knob

A thumbscrew knob near the front roller helps you adjust the tracking position of the belt. It moves the forward roller from side to side to adjust the alignment of the front and back rollers.

Speed variance

A belt sander excels at removing a lot of material at high speed. You should also be able to use your sander to do controlled sanding. That is when a variable speed motor can be helpful. Adjust the dial down the speed control, as shown in the lower center photo.

The maximum speed for belt grinders depends on several factors, including the type of abrasive grain, grit grade, and workpiece material. The higher the belt speed, the higher the cut-rate (Abrasiveboss.com).

Size

Sander tools have more surface area and weight for smoothing wide surfaces. They are for bigger work and shop use. On another note, belt grinders differ by the width and length of their belt size. It has a strong grinding capacity. That is at the expense of weight.

Belt

Belt sanders have a locking button that holds the switch in the “on” position. That helps you avoid the sander flying across the room when you plug it in. When using belt grinders, emit sparks when the abrasive belt contacts your metal workpiece by following metalworking shop safety guidelines.

Wear the proper protective clothing, and clean up any flammable materials nearby before use. Because of the abrasive nature of the belt, you do not need to apply a lot of pressure with your working material to reach your desired finish. Less is more when it comes to this process.

When using a belt grinder, you have control of the grinding process. You will be physically holding your working material. A belt grinder is an automatic machine, meaning the belt will feed through on its own, hands-free, allowing you to maneuver your material against the abrasive belt as it pulls along.

What could be better

Belt sander

- There is a need for speed management.

Belt grinder

- More pressure is for grinding.

Similar Features

- Multiple materials are used with two grinders and sanders.

- Powerful motors.

- Spin wheels and belts at high RPMs.

- Both have a variety of grits. They remove rust.

- Both can smooth out the wood.

-

Key Differences

- A belt sander is a heavy-duty tool for material removal, whether wood or metal, whereas the belt grinders are for grinding and shaping metal parts. Make sure you use the correct belt type and grit for the material that you are sanding.

- If your sanding wood using a belt sander, the wood will not burn because of the slower belt speed. The belt sander does not remove a bunch of material all at once. If you want to remove a whole bunch of material, such as remove risers from casting and a lot of steel quickly, you will need a belt grinder. The belt grinder belt speed runs double what the belt speed is running at.

- Belts grinders have multiple grinding points, such as the platen and the second grinding point is the contact wheel, unlike belt sanders.

- A belt sander works if you want to make the knife’s surface smoother. It must be soft metals. On the other hand, belt grinders are unable to operate on delicate metals due to their excessive power.

- Belt grinders need more experience than belt sanders.

- The Belt grinder leaves numerous scratch marks on the surface, unlike the belt sander.

- A belt sander runs at a lower speed and has fixed wheels. Not much adjustment is allowed. Belt grinders run faster. They have variable speeds and different attachments to allow for differing grind lines—more belt adjustment from slack to stiff than on the belt sander.

- A belt sander works for different materials, whereas a belt grinder’s purpose is metals.

- Belt sanders use sandpaper, while the grinder uses metal to perfect the piece.

- A belt sander smooths the work while a grinder sharpens it.

The verdict

Use a belt sander if you want to create curves, smooth out a surface, remove rough edges, prepare a surface for painting, or even out small surfaces. Belt grinders are for industrial facilities to grind down materials. They smooth the metals’ surfaces. A concave finish is achieved by belt-grinding a metal object if you want a concave finish.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024