What is linseed oil?

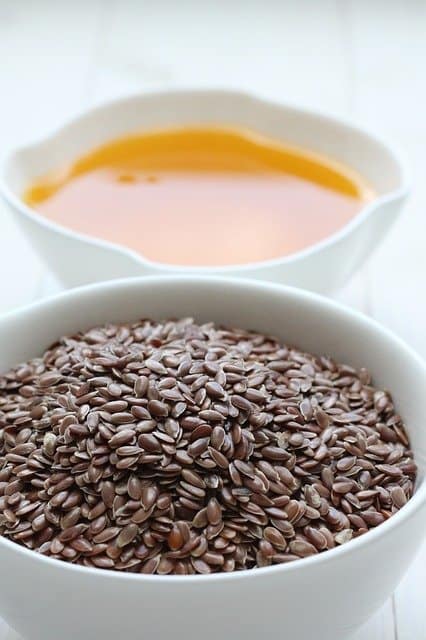

In its edible form, linseed oil, also called flaxseed oil or flax oil, is a colorless yellowish oil made from the flax plant’s dried, matured seeds. Linseed oil is a drying oil that can polymerize and solidify into a solid. Pressing is helpful to obtain the oil, occasionally followed by solvent extraction. Linseed oil is helpful as an impregnator, drying oil finish, or varnish in wood finishing, as a color binder in oil paints, a plasticizer and adhesive in putty, and as the creation of linoleum due to its polymer-forming capabilities.

Linseed oil use has reduced in recent decades because of the greater availability of synthetic alkyd resins, which perform similarly to linseed oil but do not yellow. Linseed oil’s preservative features for house repair include keeping and preventing corrosion of wood and concrete surfaces in items we depend on in all the places we live, work, shop, and enjoy, ensuring their quality and lifespan.

Characteristics of Linseed Oil?

The following are some characteristics of linseed oil that make it appropriate for industrial use:

- Drying characteristics – It dries evenly but slowly. It is ideal as a drying agent in wood finish products, paint formulas, and other applications because of this property.

- Adding radiance – Linseed oil adds radiance to wood.

- Water-resistance — Linseed oil protects a thing from moisture. And this preserves furniture from water damage and prevents metal objects from rusting.

- Binding characteristics — In several products, it aids in binding constituents. When all components are combined, they form a rich and silky emulsion.

Advantages of Linseed oil

- It is simple to use

- The glossy and rich finish

- Preserves the wood

- Is water resistant

- Much less expensive than commercially available preservatives

- It’s readily available in a variety of shapes and colors.

- Penetrates the fibers of the wood

Disadvantages of Linseed

- It takes longer to dry than Tung oil but can be sped up using solvents like turpentine and mineral spirits.

- It feels oily or sticky while drying and may not dry.

- It appears oily or sticky while drying and may not dry at all.

- It may catch fire.

- It does not provide UV protection.

- Mold growth is unavoidable.

- It is not very durable because it does not harden properly. Wax is an additional need for long-term durability.

- Refinishing is tough to remove.

- When applied thickly, it becomes soft and wrinkled.

Can you use danish oil for wood finishing?

Danish oil is suitable for finishing wood. It comes from various resins, oils, and even solvents. Because it hardens the wood beneath the surface, it works nicely on wood. It produces a natural covering that brings out the wood’s intrinsic beauty. Recoating a Danish oil finish that has deteriorated due to scratches and wear marks is a simple operation, as we described before. Danish oil finishes are not as prone to cracking as other finishes.

Several coatings are frequently applied, with a 6 to 24 hours drying interval. The application procedure is similar for most oils, with a few differences from one type to the next. For example, the application technique for danish oil differs somewhat from that of linseed oil. It is reasonably stain-resistant, so if stains or mild scuffs emerge, You can quickly remove them with simple sanding and reapplication of additional oil.

Advantages of Danish Oil:

- Simple to apply, mend, and restore

- Dries relatively soon

- Matte or satin finish in clear

- The finish penetrates easily

- Water-resistant. When you sand the surface correctly, it may even withstand hot water.

- The finish is light.

- You can paint or varnish it.

- You can use it as both a priming and a sealer.

- Smooth, non-sticky surface

- It can be put over polyurethane.

- Doesn’t yellow with age

- If you want to color, mix it with tints.

- You can wax it over.

- It has a natural appearance, but other oils are essential for a glossy appearance.

Disadvantages of Danish Oil

- Less durability than other finishes

- It needs regular application and maintenance.

- It can only be applied on bare wood.

- You can still feel the wood’s grain after finishing

- Not recommended for surfaces used for cutting (e.g., chopping board).

What varies between danish oil and linseed oil?

Danish oil originates from oils, resins, mineral spirits, and other solvents. The Danish oil formula isn’t set in stone, and the ratios and components vary depending on the brand. You can find Tung oil and linseed oil in them. On the other hand, Linseed oil is a pure oil produced from crushed flax seeds, often known as flaxseed oil. It is the most refined in its raw state, and it is also edible. It’s available in capsule form as a supplement and as frying oil in many kitchen cabinets. As a result, danish oil differs from linseed oil. Tung and linseed oil are mixed with mineral spirits, while linseed oil is natural oil produced from flax seeds.

Choosing between linseed oil vs danish oil

Linseed oil has been helpful for centuries in nourishing and protecting the wood. It is one of the most common finishing oils globally due to its ease of use and low price. Raw linseed oil, in particular, is unprocessed and contains no driers or thinners. It has a much longer drying period and is commonly used on cricket bats to keep moisture and prevent cracking and splitting. Depending on the wood stain, you can apply linseed oil. Solvent-based paints may conflict with the oil’s penetration, so only water or non-grain-raising stains are suitable.

On the other hand, Danish oil is perfect for new and untreated wood. It’s a thin oil and varnish combination with faster drying than linseed oil. It dries quickly and provides excellent protection and aesthetics than most other wood treatments on the market, such as linseed oil. Danish oil will take about 15 minutes to permeate into the wood after application. A single daily application is ideal; multiple layers will result in a thicker, more lasting coating. As a result, Danish oil is a versatile and popular option for wood finishing.

- Pyrography Techniques for Beginners: Textures and Shading - January 23, 2024

- Troubleshooting Jointer Issues: Why is Your Jointer Not Flattening Wood? - October 11, 2023

- Unlocking the Secrets of Jointing to Increase Width - September 29, 2023