Self-centering bits provide effortless precision when drilling holes. These bits, designed for pilot holes in hinge fasteners, feature a spring-loaded metal sleeve surrounding the drill bit. This innovation ensures precise hole alignment, prevents chipping on surfaces and ensures the drill bit remains centered in the workpiece throughout the drilling process. The result is impeccable craftsmanship with no deviations.

The importance of self-centering drill bits is especially apparent when fastening hinges, as even a slightly off-center screw can interfere with their function. These bits typically have hex shanks compatible with impact wrenches and cordless drills with self-centering chucks. Their usefulness extends to various installations such as metal panels, drawer runners, handles and other components that require precise hole positioning.

In the following sections, this article explores the mechanics and benefits of self-centering drills and highlights the intricacies of their operation.

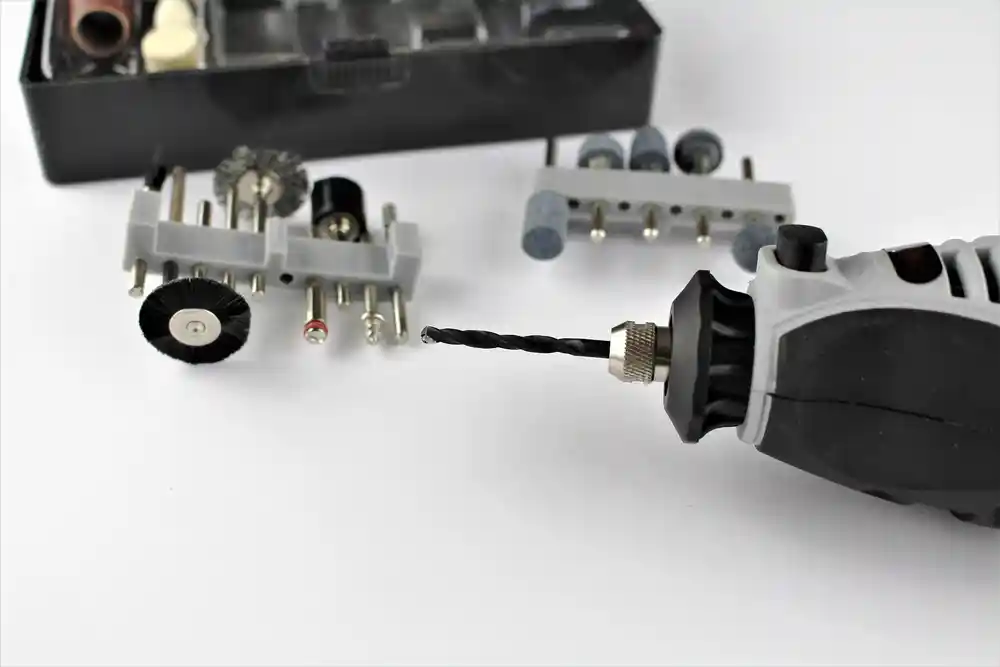

Overview of Drill Bits

Different types of drill bits

- Wood Auger Bit: Designed for drilling large, deep holes in wood, often used in construction and carpentry projects.

- Forstner Bit: Ideal for precise, flat-bottomed holes in wood, creating clean-cut, smooth holes.

- Twist Drill Bit: The most common type, suitable for drilling into various materials including wood, metal, plastic, and more.

- Spade Bit: Known for its paddle-like shape, used for rapid drilling in wood, often for rough holes.Brad Point Drill Bit: Offers accurate drilling in wood with reduced risk of splintering, thanks to its pointed tip.

- Countersink Bit: Used to create conical holes, allowing screws to sit flush with the surface, enhancing the aesthetics of woodworking projects.

- Rivet Countersink Drill Bit: Designed to create countersunk holes for rivets, ensuring a secure fit and a clean finish.

- Hammer Bit: Used with a hammer drill to effectively bore into masonry materials like concrete and brick.

- Forte_Tools Auger Drill Bit: A specific brand or type of auger bit designed for reliable wood drilling.

How to drill bits work

The point of the bit contacts the material you are drilling into, while the shank is clamped in place by the jaws of a drill chuck. An electric drill converts electricity into mechanical energy using an electric motor. As the drill bit bites into the material you are drilling, the mechanical energy is converted into heat energy. For holes, attach drill bits to a drill, which powers them to cut through the workpiece, typically by rotation (Instructables.com).

Types of drill bits used for wood, metal, and concrete

- Use twist bits to drill holes in flat surfaces, depending on the material you are drilling. To complete the job, use a different twist drill for metal, wood, and brickwork.

- Steel bits are the softest, cheapest bits for drilling wood or plastic. They drill through harder materials like brick or metal, but they will blunt quite quickly.

- High-Speed Steel (HSS) Bits are a little tougher and can drill through harder materials quicker and without blunting.

- Masonry bits are larger twist drills with a slightly tighter corkscrew shape. They are easy to identify with their wide arrow-shaped heads. You can use them on brickwork, stone, breeze blocks, and other hard stone surfaces. They also work on wood, although the hole will be ragged and takes longer than a proper wood drill.

What are Self-Centering Drill Bits?

Self-centering drill bits provide a new level of accuracy in drilling. Unlike conventional bits, they ensure precise drilling at the intended center point with minimal effort. These drills feature a spring-loaded metal shell that surrounds the drill bit. This design automatically centers the drill bit at the position of the hole and prevents slipping or skipping during drilling. The result is centered holes critical to the installation’s integrity.

A primary application is the installation of hinges. Misaligned holes cause screw positioning problems and affect hinge movement. Craftsmen use these bits for perfectly centered holes that ensure smooth operation of hinges.

They’re also essential for accurate hole placement, such as mounting base plates, drawer slides, handles and fixtures. Their ease and precision are valuable in woodworking, carpentry and projects that require precise alignment.

How they differ from regular drill bits

Self-centering drill bits accurately center and drill holes in wood, while regular bits lack a guide and depend on the user for centering and alignment.

Advantages of using self-centering drill bits

- Accurate and precise hole drilling.

- Reduced risk of bit wandering due to the centering guide.

- Faster and easier drilling process.

- Versatility across materials like wood, metal, and plastic.

- Cost-effective, offering valuable functionality for the price.

How Self-Centering Drill Bits Work

The inner mechanism of self-centering drill bits

The tip remains inside the spring-loaded sleeve as you position the drill tip of the sleeve in the matching hinge. When drilling, push the drill bit down as the spring-loaded sleeve remains in place. The sleeve guides the drill bit to remain perfectly centered and straight. When you remove the drill bit from the workpiece, the sleeve moves back in place, covering the drill bit once more.

How do they locate the center point of the hole?

A center punch is used to establish the starting point of the hole, which dictates the direction of the hole. As a rule, a single center punch with a length of about 100 mm is used. (Instructables.com).

Role of the pilot tip

A pilot drill establishes a smooth and consistent surface, enabling the drill to initiate entry into the workpiece seamlessly.

How to use self-centering drill bits properly

Using self-centering drill bits properly:

- Prepare the Workpiece: Mark the installation location and, if needed, rout the area to ensure proper fitting.

- Mark Drilling Position: Use a woodworking pencil to mark the drilling spot. Place the piece and mark the holes for hinge or kickboard installation while keeping the feature in place.

- Secure the Workpiece: Hold the feature down with one hand or use a clamp to secure it, depending on your experience.

- Install the Drill Bit: Insert the self-centering drill bit.

- Position the Bit: Align the tapered end of the spring-loaded sheath securely into the hinge hole, ensuring a centered hole. Hold the drill vertically.

- Start Drilling: Activate the drill and begin drilling. Apply consistent pressure to the bit until the desired depth is reached. Drill at a controlled pace for better accuracy. Remove the bit after completing the hole.

- Manage Deep Holes: For deep holes, periodically remove the bit from the hole every ¼” to prevent material accumulation in the sheath.

- Repeat the Process: Follow the same procedure for the remaining holes.

Choosing the Right Self-Centering Drill Bit

Different types of self-centering drill bits

Various types of self-centering drill bits include:

- Hinge Self-Centering Bits: Specifically designed for hinge installation, these bits ensure precise alignment of screw holes, optimizing hinge functionality.

- Countersink Self-Centering Bits: These bits create conical recesses for screws, enabling them to sit flush with the surface, enhancing aesthetics and preventing splintering.

- Drawer Slide Self-Centering Bits: Tailored for drawer slide installation, these bits accurately position holes for smooth drawer movement.

- Cabinet Handle Self-Centering Bits: Used to align holes for cabinet handles, these bits maintain consistent spacing for a polished look.

- Kick-Plate Self-Centering Bits: Ideal for metal kick-plate installation, these bits ensure accurate hole placement for secure fitting.

- Fixture Self-Centering Bits: Versatile bits for various fixtures, offering precise hole alignment in a range of applications.

These self-centering drill bit variations cater to specific installation needs, guaranteeing accurate hole placement and streamlined results.

Which self-centering drill bit is best for wood, metal, and concrete

For wood, metal and concrete applications, self-centering twist bits, commonly called fluted bits, offer versatility. These bits suit light metals, wood, plastics, ceramics and masonry.

Factors to consider when selecting a self-centering drill bit

When choosing the right self-centering drill bit, several factors come into play to ensure optimal performance and accurate results:

- Drill Bit Size: Select a drill bit size that matches the hole diameter you intend to create. A proper fit prevents excess material removal and ensures a snug fit for screws or fasteners.

- Drill Bit Material: Consider the material of the drill bit itself. High-speed steel (HSS) bits are versatile and commonly used for various materials, while cobalt and carbide-tipped bits are suitable for tougher materials like metal and masonry.

- Loaded Spring Quality: The quality of the spring mechanism within the drill bit affects its self-centering capability. Choose a drill bit with a reliable and well-constructed spring that ensures consistent centering throughout the drilling process.

- Rotational Speed: Adjust the rotational speed of your drill based on the material you’re working with. Slower speeds are often recommended for harder materials like metal and concrete to prevent overheating and ensure accurate drilling.

Considering these factors will help you choose the most appropriate self-centering drill bit for your specific task, promoting efficiency and precision in your work.

Tips for Using Self-Centering Drill Bits

Proper technique for using self-centering drill bits

To effectively utilize self-centering drill bits, follow these steps for bit replacement and maintenance:

Bit Replacement:

- Begin by loosening the set screw that secures the current drill bit in place.

- Carefully remove the old drill bit from the chuck of your drill or driver.

- Select the appropriate replacement self-centering drill bit for your task.

Spring Replacement:

If the self-centering drill bit features a replaceable spring mechanism, you can maintain it by following these steps:

- Unscrew the hex-drive shank from the knurled body of the drill bit assembly.

- Carefully remove the old spring and replace it with a new one of the same specifications.

- Reattach the hex-drive shank to the knurled body securely.

How to avoid common mistakes while using self-centering drill bits

To ensure accurate results and prevent common errors when using self-centering drill bits, follow these guidelines:

- Begin with a Smaller Bit: To counter the tendency of drill bits to wander, start by using a smaller pilot bit. This initial hole provides a stable point for the self-centering bit to engage and helps maintain precision.

- Reposition If Wandering Occurs: If the drill bit begins to wander off track, pause immediately. Realign the bit with the desired drilling location, ensuring it’s properly centered. Once repositioned, continue drilling slowly and steadily.

- Utilize Pilot Holes for Thick Materials: When working with thicker materials, create a pilot hole before using the self-centering bit. This preliminary hole acts as a guide and prevents the bit from deviating while entering the material.

By adhering to these practices, you’ll minimize the risk of errors and achieve consistent, accurate results with your self-centering drill bits.

Safety measures when using self-centering drill bits

Ensure your safety when working with self-centering drill bits by following these precautions:

- Clear Workspace: Maintain a two-foot perimeter around the drill press, keeping people, debris, and sawdust away to prevent slips.

- Protective Gear: Wear safety glasses or a face shield to shield your eyes from potential debris.

- Ventilation: Maintain proper ventilation by keeping drill air vents unblocked.

- Sharp Bits: Always use sharp drill bits for efficient and safe drilling.

- Cord Management: Keep all cords clear of the cutting area to avoid entanglements during operation.

- Appropriate Pressure: Apply appropriate pressure while drilling, avoiding excessive force that can lead to accidents.

- Drill Stop Usage: When using a self-centering drill bit, always employ a drill stop to prevent the bit from going through the material entirely.

Adhering to these safety measures ensures a secure and productive drilling experience.

Benefits of Self-Centering Drill Bits

Compared to conventional drills, self-centering variants offer improved efficiency. These drills offer greater accuracy, faster drilling, and reduced risk of material damage during operation.

Precision is a hallmark of self-centering drills. Designed specifically for careful hole drilling, they feature precise alignment — especially important when assembling hinges or other components.

The time-saving benefits of using self-centering drills are substantial. This versatile drill bit set includes several sizes, all made of high-speed steel. This durability ensures they are suitable for drilling through wood, PVC and metal surfaces, simplifying your drilling operations.

Limitations of Self-Centering Drill Bits

Material limitations for self-centering drill bits

The material the drill bits are of determines the performance of the drill bit. Tougher materials, like carbide, drill through any surface. High-speed steel is for multipurpose applications due to its toughness. For metallic surfaces, consider bits made of cobalt. Cobalt blended alloys have high heat dissipation properties, which allow them to drill efficiently.

Size limitations for self-centering drill bits

A drill bit set contains various sizes of drill bits for different-sized holes. When drilling centered holes in softwood, use smaller sizes of self-centered bits. But if you are drilling centered holes in hardwood, use larger-sized drill bits.

Difficulty using self-centering drill bits for angled holes

A self-centering drill bit is helpful for completely vertical drilling holes or angles, which can be challenging to do with a standard drill bit.

How to Maintain Self-Centering Drill Bits

How to clean self-centering drill bits

Clean your bits to remove debris from the surface, either by washing with a brush, soap, and water or by immersing in acetone for five to 10 minutes.

Proper storage for self-centering drill bits

Screw sturdy magnetic strips along a 2×4 and install them on the wall of your work area. Your drill bits will stick to the magnetic strips, making them easy to grab.

How to sharpen self-centering drill bits

- Don your goggles and turn on the bench grinder.

- Get a firm grip on your drill bit and hold the cutting edge parallel to the front of the grinding wheel. Move the bit until it contacts the wheel.

- Keep it straight and held at the original factory angle of 60 degrees.

- Hold the bit at this angle against the wheel for less than four to five seconds.

- Dip the drill bit into the ice water to cool the metal.

DIY Projects Using Self-Centering Drill Bits

Examples of DIY projects that use self-centering drill bits

- Hinges

- Screw-mounted hardware

How to use self-centering drill bits in DIY projects

- Position the tip of the sleeve in the matching hinge.

- Push the drill bit down, the spring-loaded sleeve remains in place. The sleeve guides the drill bit to remain perfectly centered and straight.

Ideas for DIY projects that require precision drilling

- Replacing cabinet hardware.

- Make a coat rack.

- Replacing drawer slides.

- Craft a wood doormat.

- Make a DIY candle holder.

Best Brands of Self-Centering Drill Bits

Overview of the top brands of self-centering drill bits

Snappy Tools 40050 has all the sizes you will likely need. Other brands offer some of the same capabilities but not all in one package. Bosch CC2430 Clic-Change Self-Centering Bit Set has a high quality trusted self-centering drill set.

Comparison of features and benefits of different brands

Snappy Tools 40050 consists of five bits for any size hole or hardware, top-quality springs, and a chip-clearing design. However, it is not affordable. Bosch CC2430 Clic-Change Self-Centering Bit Set features three bits for any size hole or hardware, top-quality springs, and chip-clearing design, but it does not include larger bits vs. 5-piece sets.

Customer reviews of the best self-centering drill bits

Comoware Self-Centering Drill Bit is one of the most durable drill bits thanks to the high-speed steel material used. Self-centering drill bits keep the drill bit from wandering on a broken steel stud.

Frequently Asked Questions (FAQs)

What are the benefits of using self-centering drill bits?

The advantages of using self-centering drill bits include their speed, precision, and user-friendly nature.

How do self-centering drill bits differ from regular drill bits?

Self-Centering drill bits accurately center and drill holes in wood, whereas regular drill bits do not have a guide.

What materials can self-centering drill bits drill into?

Self-centering drill bits can drill into plastic, metal, and concrete materials.

Can self-centering drill bits be used for angled holes?

Self-centering drill bits are indeed suitable for creating angled holes.

How do I choose the right self-centering drill bit for my project?

Choose the appropriate self-centering drill bit for your project by considering the material you need to drill.

How do I properly use self-centering drill bits?

Properly use self-centering drill bits by ensuring they are sharpened and securely clamping your material.

How do I maintain my self-centering drill bits?

Maintain self-centering drill bits through regular sharpening and proper storage.

What are the limitations of self-centering drill bits?

Self-centering drill bits offer accuracy and convenience, but they also have their limitations. A major drawback is their limited size range, which makes them less flexible for projects that require different hole diameters.

What are some DIY projects that use self-centering drill bits?

Self-centering drill bits are versatile tools that enhance accuracy in various DIY projects. Consider incorporating them into the following creations:

- Hinge Installation: Achieve precise hinge positioning when crafting doors or cabinets.

- Cabinet Hardware: Ensure flawlessly aligned holes for knobs and handles on cabinets and furniture.

- Coat Rack: Craft a functional coat rack with uniform, evenly spaced hooks.

- Drawer Slide Installation: Attain smooth and reliable drawer movement using self-centering bits for slide installation.

- DIY Candle Holder: Create custom candle holders with accurately positioned holes for candle placement.

What are the best brands of self-centering drill bits?

Reputable brands known for producing high-quality self-centering drills include Bosch, Werkzeug, QWORK, Snappy, and GORCHEN. These brands are known for their reliability and effectiveness in various drilling applications.

Conclusion

In conclusion, self-centering drill bits are more versatile than regular bits. They work on metal, plastic, and concrete. Keep them sharp enough for drilling, and use the right size for your project. Use a specific drill for your material. Be creative enough to make DIY projects with your drill bit. Self-centering drill bits are fast and precise in drilling holes.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024