What is a servo motor?

A servo motor is a rotary actuator that allows precise angular or linear position, velocity, and acceleration. It consists of a suitable motor with a sensor for position feedback. It requires a controller, a dedicated module designed for use with servomotors with the help of servomechanism.

What are the applications of a servo motor?

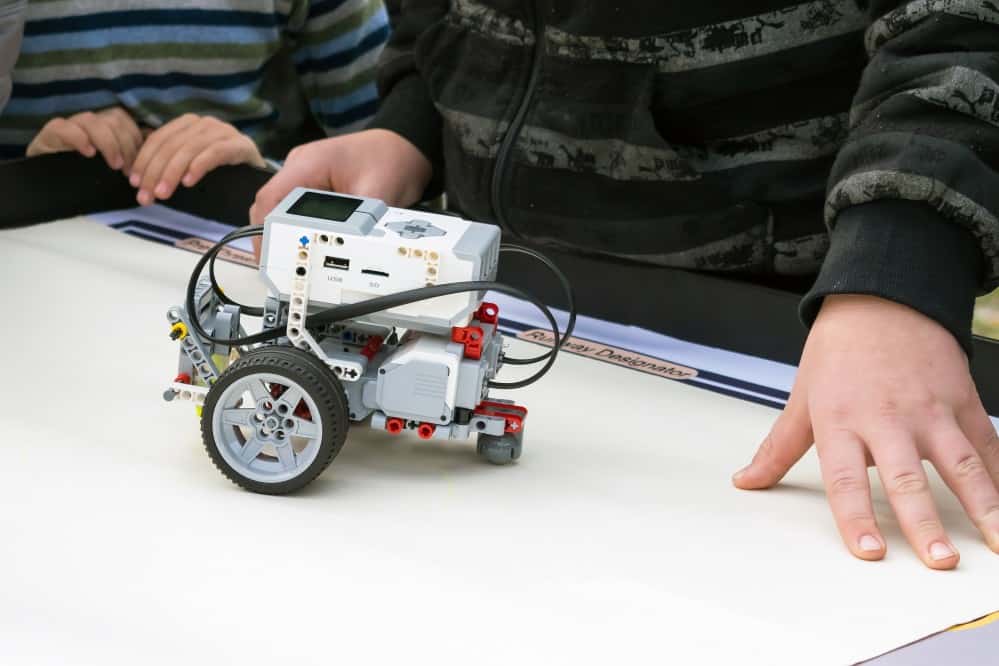

The applications of these motors include industrial robotics, computers, toys, CD/DVD players. These motors are in some applications where a specific task is to be done regularly in an exact manner. One of the popular servo motor applications is in robotics. Look for a simple pick and place robot.

What is a stepper motor?

A stepper motor, also known as a step motor or stepping motor, is a brushless DC electric motor that divides a full rotation into several equal steps. They have multiple coils organized in groups called phases. These are for fluctuating loads. Torque is high in speed, and there is a high-tolerance movement of inertia.

What are the applications of a stepper motor?

- 3D printing equipment

- Textile machines

- Printing presses

- Gaming machines

- Medical imaging machinery

- Small robotics

- CNC milling machines

- Welding equipment.

Which is better: servo or stepper motor?

Servo motors are better than stepper motors. They run faster than stepper motors, with speeds on the order of several thousand RPMs. This enables servo motors to be used with gearboxes to deliver much higher torque at speeds.

Servo motors generate more noise but are fast and more powerful. Servo motors are limited to 180 degrees or less rotation while steppers are quieter and have no limit on rotation. Steppers are bigger and heavier.

Can stepper motors run continuously?

Yes, stepper motors run continuously. You need a saw motor that can be precisely driven. That is a motor reliable enough to run continuously.

When would you use a servo motor?

Servos are used on angular or linear positions and for specific velocity, and acceleration. Companies use servo motors because of how compact and potent it is. Despite its size, it produces power and is known to be energy-efficient.

They are used in applications to control speed and position and output torque. Servo motors replace conventional AC motors, stepper motors, and hydraulic and pneumatic systems.

Which motor has the lowest position accuracy?

Unlike Stepper motors that have remarkable stopping accuracy and accurate control with open-loop, servo motors have the lowest position. How powerful is a stepper motor?

How much torque can a servo produce?

Servo motors can deliver torques of up to 250 foot-pounds. The combination of speed and torque enables servo motors to deliver better acceleration than stepper motors.

Why would you choose to use a stepper motor instead of a servo motor?

Servo motors generate more noise (electrical) but are fast and more powerful. Servo motors are limited to 180 degrees or less rotation. Steppers always are quieter and have no limit on rotation. Steppers are bigger and heavier.

What is the difference between a DC motor servo motor and a stepper motor?

A stepper motor is a servo motor that uses a different method of motorization. A servo motor uses a continuous rotation DC motor and an integrated controller circuit. Stepper motors utilise multiple toothed electromagnets arranged around a central gear to define the position.

What is the similarity between a stepper motor and a servo motor?

Both servo and stepper motors can provide reliable power for a highly effective system. They both have the following features: high positional accuracy and compact mechanical assembly.

How is the movement of a stepper motor different from that of a servo or Scim?

A servo motor turns to whatever angle the controller instructs it to, regardless of the initial position at power-up. A stepper motor’s lack of feedback does limit its performance since stepper motors only drive a load that is within its capacity.

What are the advantages of servo motors over stepper motors enlist some of the industrial applications of servo motors?

- High efficiency

- High output power

- It comes with more constant torque at a higher speed

- Closed-loop control

- Quiet operation

- Highly reliable

- High ratio of torque

- High acceleration.

Which motor is more suitable for precise position control?

Servo motors are used in small remote control models and robotics. Most servo motors rotate up to about 180 degrees in both directions, making them ideal for accurate angular positioning.

What is the main disadvantage to using a stepper motor over a servo motor?

- The Stepper motor draws significant power regardless of load. When compared to Servo Motors, Stepper Motor has low accuracy

- Which are the limitations of the stepper motor?

- The feedback loop is not used

- These motors produce extremely high noise

- Not easy to operate at high speeds

- Complete motor failure. This problem is caused by excessive current sent to the device by the power supply

- Low efficiency

- Low accuracy.

Can we use a stepper motor instead of a servo motor?

Yes, you can get the same torque from a stepper motor as from a servo motor. You will get higher performance from a servo, with a more flexible speed curve and an extra time-dependent peak torque rating. An optimized stepper motor can do the same job.

Is a stepper motor the same as a servo motor?

Servo motors are more sophisticated than stepper motors. The main difference between these motors comes from the overall pole count. Stepper motors have a high pole count, between 50 and 100, while servo motors have a low pole count between 4 and 12. Servo motors require an encoder to adjust pulses for position control.

Can a stepper motor run continuously?

Yes, it runs continuously. Stepper motors fall in between a regular DC motor and a servo motor. They have the advantage that they can be positioned accurately, moved forward or backward one step at a time, but they can also rotate continuously.

What is the max RPM of a stepper motor?

Stepper motors operate at high rpm based on the maximum motor speed rating of 3000 rpm and the motor torque vs. speed curves.

Can a stepper motor rotate 360?

Yes, it can. It has a rotating shaft, is a rotational motor as others are. The difference is you can position the shaft to an arbitrary position, to the desired angle of rotation.

Are stepper motors accurate?

They are accurate but not more than servo motors. The motor operates by accurately synchronizing with the pulse signal output from the controller to the driver, achieving highly accurate positioning and speed control.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024