What are the different types of table saws?

Generally, Table saws fall under two kinds of table saws: portable table saws and stationary table saws. The two types have the following table saws.

- Stationary Table saws

- Hybrid table saw

- Contractor Table saw

- Cabinet Table saw

- Portable Table saws

- Jobsite Table Saw

- Benchtop Table saw

- Compact Table Saw

What is a Jobsite table saw?

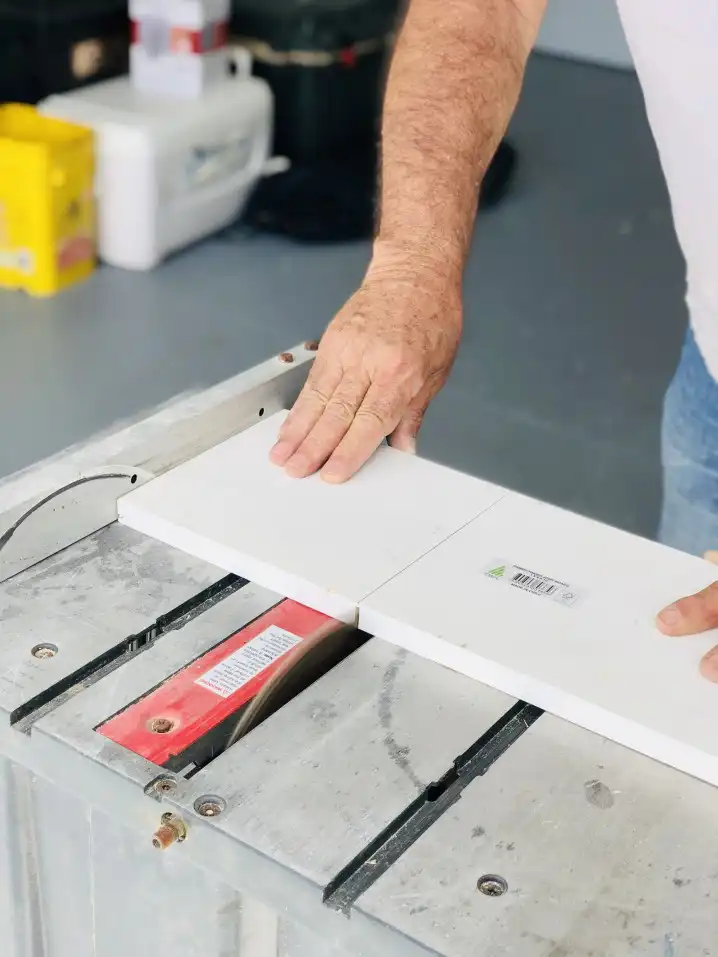

Jobsite table saws are famous for their remarkable convenience and small and ergonomic design. Compared to benchtop or compact table saws, they are more powerful and durable. Temporary employees are drawn to the ease of a portable table saw, so some carpenters and woodworkers refer to them as contractual worker table saws.

They have direct-drive engines, making them more spectacular and sturdier, suitable for heavy-duty applications. They also come with better fencing and arrangement changes, 24″ tear restrictions, and some even come with expansion tables.

The Jobsite saw stand is one of its best features. The stand is composed of a clever design that is simple to move around. Aside from that, the stand has heavy-duty wheels for increased versatility. You can also fold them to save room in the garage when not in use. A job site with a dust port, riving knife, and onboard storage space, among other features, is considered a worthwhile investment.

What is a hybrid table saw?

The system allows a contractor saw and a heavy-duty cabinet saw. A stand with wide legs is standard on hybrid table saws. However, a few models have completely fenced-in areas, adding to the confusion and making it difficult for buyers to distinguish between hybrid saws with fully fenced-in areas and modern cabinet saws. The resemblances are primarily superficial.

There are two hybrid tune-ups to identify the best hybrid table saw models. They end up in both the cabinet-mounted and table-mounted tune-ups. On the other hand, a decent hybrid saw will offer business success.

What is a benchtop saw?

Benchtop saws are ideal for folks who have a small amount of work. To a large part, they are compact, lightweight, and very affordable. On the table or bench, the saw will be together in place. Despite the lack of a platform or wheels, you can easily carry the portable table saw around because of its lightweight.

To make them simpler to move around, they are built of highly lightweight materials such as plastic, aluminum, or similar materials. They have a smaller table and a reduced ripping capacity. It may, however, cut any material according to the plan.

How many kinds of mitre saws are there?

Standard Mitre Saws, Sliding Mitre Saws, and Compound Mitre Saws are the three varieties of miter saws.

A standard miter saw is the common primary type of miter saw, with a blade on the arm mounted to the base and can make bevel cuts between -45° and +45° degrees.

The sliding miter saw, and the compound miter saw are nearly identical. The main distinction is the material breadth that it can handle. It can, however, be ideal for both miter and bevel forms of cutting.

The compound miter saw is far more practical than the standard miter saw. More than just miter cuts will be possible. With an arm in its blade, it can cut at a 90-degree angle.

The saw has the advantage of performing the more specialized or essential cutting. Furthermore, it’s ideal for cutting angles, bevels, and angled bevels. The width of the blade determines all of the cuts.

What is the name of the removable insert on a table saw?

The throat plate will be on the table’s top; this is nothing more than a moveable component that allows you to reach the blade. The blade slot is the most crucial portion of the neck plate.

How do I know which table saw to buy?

A table saw is one of your workshop’s most flexible and necessary instruments. When you’re ready to buy one, look at all of the different designs and features to make sure you’re getting one that will meet all of your cutting requirements.

How powerful of a table saw do I need?

A table saw with a 2-HP motor moving 15 Amps should suffice for hobbyist DIY projects. This table saw may be powered by a 120-volt outlet. Look for table saws with 3-5 horsepower engines. These table saws require a 220-volt power supply.

What size table saw should I buy?

For different reasons, size and portability are vital to all woodworkers. A professional contractor is likely to be more concerned with the ease with which the table saw may be transported from job site to job site. The weight of the cart isn’t nearly as significant as the ability of the cart to stand.

The size of a table saw will depend on the size of the workshop for both professional woodworkers and weekend enthusiasts. Benchtop table saws are the tiniest, while cabinet table saws are much more significant. Even hybrid table saws, which are pretty large in their own right, are sometimes equipped with caster wheels for mobility within a workshop.

How much should you spend on a table saw?

It’s critical to understand your financial constraints. The top table saws range in price from $300 to $3000 and beyond. The fact is that there are numerous table saw models available, each with its own set of functions, accessories, features, and costs. However, for around $200-250, you can purchase a well-used table saw that works well.

How much rip capacity do I need on a table saw?

Most entry-level table saws have a rip capacity of 28 inches, with 30 inches being the most common. With a rip capability of 28 inches, you can complete most rip cuts.

What is the difference between a cabinet saw and a contractor saw?

Cabinet saws contain more cast iron and steel in their construction and more oversized trunnions, gears, arbor assembly, and more powerful motors than contractor saws.

The motors on contractor saws are exposed, whereas the motors on cabinet saws are enclosed.

Contractor saw motors are considerably more potent than cabinet saw motors.

What is a contractor table saw?

Professional woodworkers have long used contractor saws as a smaller, more controllable alternative to cabinet-style table saws for expert carpentry and building, medium to large furniture and construction projects, heavy-duty home renovation, and do-it-yourself projects.

What is a Cabinet saw used for?

Among table saws, the cabinet saw appears to be the best. Only the cabinet table saw can equal the cabinet table saw’s combination of precision, power, and rip capacity. They’re most known as the focal point of professional woodworking shops, where they act as the hub for all construction and furniture-making operations. They’re big, expensive, and difficult to transport.

Do you need a table saw for cabinet making?

Without a table saw, you can build your cabinets. The Plywood for the upper corner cabinet, on the other hand, must be cut at a 45-degree angle along one edge. The correct equipment is the difference between efficient projects with precise joinery and sloppy jobs where nothing fits or aligns. Investing in the most incredible tools yields a difficult-to-beat return. On the other hand, a table saw will make cabinet building much more manageable.

What is the difference between a table saw and a circular saw?

Table saws are large, heavy, and difficult to maneuver. Circular saws are smaller, lighter, and more portable than other saws. If necessary, they may also be valuable as a table saw, although table saws are not ideal as circular versions.

Cutting capabilities are another distinction between a table saw and a circular saw. Table saws can make accurate rip cuts and crosscuts, but they can’t make notches or bends. If you need to make any of these cuts, you can use a circular saw.

How do you make a table saw cabinet?

Tools to Use

- Kreg K4 Pocket hole jig

- Kreg Accu-Cut

- Kreg Cabinet Hardware Jig

- Kreg Deep Face Clamp

- Parallel Clamps

- Trim router

- 18ga brad nailer

- Circular Saw

- Tablesaw

- Mitre Saw

Materials/Supplies

- (2) 4′ x 8′ 3/4″ Plywood

- (1) 4′ x 8′ 1/4″ Plywood

- (7) 22″ Drawer Slides

- 1-1/4″ Pocket Hole Screws

- 1-1/4″ Wood screws

- (7) Drawer Pulls

- (4) 3″ casters

- Build the cabinet carcass

Using the Kreg Accu-Cut track and the cordless circular saw, cut down the entire sheets of Plywood to a manageable size. Cut the top, bottom, and sides to the extent using the table saw cabinet designs, then use the K4 jig to drill pocket holes in the underside of the top and bottom panels. Use 1-14″ pocket screws to link the top to the sides and the rest of the project. To keep everything in place, use long clamps.

- Install the sliding panels

This DIY table saw cabinet has five drawers in the middle and vertical sliding panels on the exterior. Cut four vertical dividers to width after cutting the sliding panels to size on the table saw. Then, cut the dividers to fit the cabinet’s opening using your miter saw.

- Build the cabinet drawers

It’s now time to build the cabinet drawers. Always utilize preferential measures for the fronts and backs of cabinet drawers. Cut the drawer sides to length and leave the front and back slightly long. To account for the drawer slides, measure the drawer opening and subtract 1″ from the measurement. After that, rip all of the pieces to the final drawer heights.

- Mount the cabinet drawers

Begin placing the drawer slides in the table saw cabinet once the drawers are complete. Begin by positioning the bottom drawer slide with a large spacer. Then pre-drill and screw it in place.

- Cut and install the drawer fronts.

You can attractively finish the front of the table saw cabinet with false drawer fronts. Use a single piece of Plywood. To achieve a continuous grain look:

- Cut the panel to size, then remove the vertical shows on the left and right.

- Cut each drawer front to the appropriate size.

This method also has a built-in 1/8″ reveal between all blade kerf sections.

- Install cabinet hardware and casters

Flip the table saw cabinet around and add a full 34″ back at this point. The strongback allows you to square up and secure the cabinet. After adding the cabinet hardware and casters, you can now be proud of your DIY table saw cabinet.

- Pyrography Techniques for Beginners: Textures and Shading - January 23, 2024

- Troubleshooting Jointer Issues: Why is Your Jointer Not Flattening Wood? - October 11, 2023

- Unlocking the Secrets of Jointing to Increase Width - September 29, 2023