The scroll saw is a fantastic tool for cutting intricate patterns and designs in wood. Using a scroll saw takes practice and patience. Once you master the basics, you’ll be amazed at the projects you can accomplish!

How to use a scroll saw: scroll saw basics

When you use a scroll saw, follow these steps. I will guide you as either a hobbyist or a professional user.

You cut your board into a perfect size for your scroll saw. The surface of your wood has to be in blue painter’s tape. Use your fingernail to check the tension of your blade. The blade has to be squared to the table and be prepared to switch on the scroll saw.

Place your material on the table, follow the outline of the pattern on your board and run your pattern. You can lower your speed using the adjustable knob when you have difficulties staying on the line. When done, remove the tape and sand down the edges. You may add coating depending on the kind of finish you want to have.

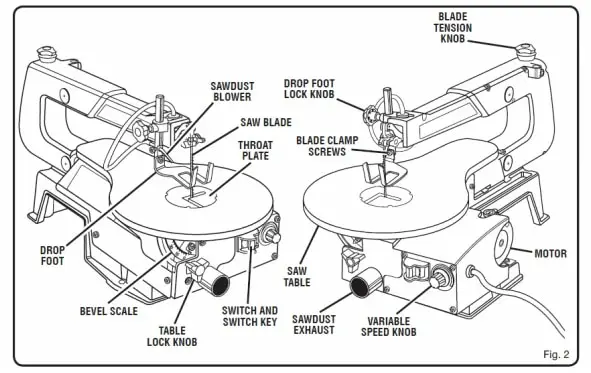

Parts of a scroll saw

Blade

Scroll saws use a slender blade that moves in an up-and-down movement. The movement ranges from 400 to 1,800 strokes per minute. The speed does not mean the scroll machine is dangerous to use. The blade cuts through various materials such as plastic, glass, and thin metal.

Flat table

The table is where you place your material for sawing. The arm extends above the table as it connects the saw blade. A hole in the table connects the saw blade to the motor, and the drilled hole is under the table.

Base

The base is the bottom of the saw. It works as a bench for the scroll saw as it supports the scroll machine. It comes with legs that make the scroll saw mobile and balanced. Some scroll machines have foldable legs for easy storage and easy handling.

Throat

The throat is the part of the scroll machine at the back. Standard saws have a throat capacity of 12 to 30 inches.

Dropfoot

A drop foot is an attachment that allows you to scroll large materials. This attachment allows you to make decorative cuts in wood and plastic.

Rack and pinion

The rack and pinion is a mechanism that gives you a hand-crank option instead of the push button option. The hand crank will stop automatically once your cut ends.

Dust blower

A dust blower is an attachment that helps you avoid breathing in sawdust produced by the machine when cutting different materials.

Bevel Scale

The bevel scale gives you an accurate measurement of the angle at which you cut your material.

Vice

The vice holds your workpiece in place as you cut it. Some scroll saws have two parts: the vice and the table.

It is located at the base of the scroll saw to work on large materials and move them without ripping or breaking.

Clamping Table

A clamped table is an accessory that helps you cut various materials, including wood, plastic, leather, and metal. Some clamps even allow you to clamp multiple materials together for a more stable workpiece.

Variable speed knob

The variable speed knob allows you to change the speed of the scroll machine. Some scroll saws have two speeds: a slow speed and a fast speed. It also ranges in speeds from 560 to 5,000 strokes per minute.

Blade guards

Blade guards protect your hands and fingers from accidental injuries by covering the blade.

Quick release blade clamp

A quick-release blade clamp is an accessory that allows you to quickly release the blade when needed so you can switch it with another.

Blade clamp screws

Blade clamp screws are required for mounting the blade into the scroll machine.

Center post

The center post is made of aluminum and is used to support the material you are cutting.

Quick change spindle pulley

A quick change spindle pulley makes it easy to rotate the blades around different parts of your scroll machine.

Switch and Switch Key

The switch and switch key is a tool you use to control the scroll machine.

The switch connects the blades to the motor. The switch also controls how fast the blade moves up and down. You make adjustments to various parts of your scroll machine using this tool.

Belt tension gauge

A belt tension gauge allows you to adjust and change the belt for various parts of your scroll saw. A professional use this accessory to make fine adjustments before he starts cutting different materials with it.

How to change blades

Most scroll saws come with manufacturer instructions. Refer to those first. They tend to be more specific to a tool than general information.

It saves you from buying another set of scroll saws. There are also different types of teeth on blades, and these are features you have to look into so that when you have to replace your saw blade, you do not buy the wrong saw blade.

Pin-end blades are more accessible to change than flat ones. However, they do not last long on tight turn cuts and do not come in a wide range. The flat blades have different shapes that make them versatile, and they are not easy to change but perfect for tight turns.

Turn off the scroll saw machine by unplugging it, which avoids accidents. Look for the bolts and loosen them. They are at the top and below the scroll saw. You are allowed to use a screwdriver or Allen wrench. Do not remove the bolts altogether so that you do not lose screws.

Get rid of the old blade. Examine the sharpness of the saw blade and the direction of the teeth. Insert the new saw blade from the opposite direction you took out the old saw blade. Lock it in place using pliers. Tighten the bolts and test the saw.

Attaching the scroll saw

Since you need to hold the saw firmly when operating, the scroll saw comes with a base that has holes. These are fastening holes. Place your tool on the tabletop and mark with a pencil where the holes are. Drill the holes through the saw and the saw tool.

Hold it in place and trace the holes with a pencil. Remove the tool, drill holes, and put the scroll saw back on the table. Secure the saw using bolts and screws.

Fitting blades

- Unplug the saw

- Release blade tension

- Loosen blade mounts

- Insert the blade paying attention to the direction of the teeth

- Tighten the blade mounts

- Re-tension the blade

- Plugin the saw

- Run test cuts

Scroll saw safety

The scroll saw has to be secured firmly to the tabletop or workbench. Switch off the scroll machine from power. Unplug the cord when making adjustments, changing the blade, making repairs, running maintenance, and when not in use.

I urge you to use the exact blade type regardless of the low cost or how similar they look to the required saw blade. It does not have to be the best blade but the best for your running cuts. The blade’s teeth must point forward and down toward the table, and you must focus on proper blade tension.

The table has to stay clear. The handles have to be clear before you turn the scroll saw on. Do not reach under the table when the scroll saw is still running. Keep a two-foot perimeter around the scroll saw, not occupied by people.

No matter how safe your machine is, wear safety glasses. You have to work from well-ventilated areas due to the dust created. Put on a mask or a respirator. I advise you to wear tight-fitting clothes and tie your hair so it does not get in the way of the saw. Inspect the saw before you turn it on.

Lower and adjust the hold-down foot button, so it rests on the workpiece. Keep your fingers away from the saw blade as much as protection from the blade. Your fingers have to stay away from the same line as the saw blade because the chances are high that you will hurt yourself if you slip.

The blade should not contact the workpiece before you start sawing. Hold the board firmly. Use the appropriate seed required for the type of wood. Relief cuts are made before sharp cuts. The wood material has to be flat at the bottom before cutting. Release the blade tension when done cutting. Clean your table whenever you finish a project.

How to pick the right scroll saw for you

Need

You must be true about why you need the scroll saw. It will not help you buy a scroll saw and later find out that it does not complete the tasks you want. If unsure, I advise you to go for a versatile scroll machine.

Speed

You have to be conscious of speed. Speed ranges from 400 to 800 strokes per minute, and the blade speed goes up to 1,800 strokes per minute but bears in mind that the faster the scroll machine, the steeper the price.

Different materials require different blade speeds, and softwood needs low blade speeds. Scroll machines allow you to adjust speed depending on the material you are cutting, although they come at a price. That goes back to your need and tells you the speed you need on the scroll machine.

Blade type

There are pin blades and flat blades. 2in1 blades have both saw blades on both sides, although they are not affordable. Write down your needs to know the type of blade you want, which will not cost you much. Each blade type has pros and cons; the sooner you know them, the better.

Reviews

I advise you to go through the reviews on the scroll saw you want to buy. There are thousands of models and designs, and getting the perfect one takes time. The best teacher is experienced, so reviews are a quick and informative way of getting to know a product. Checking reviews done by experts will lead you to your top scroll saw.

Budget

No matter how good a scroll saw is, you do not get it if it is way out of your budget. I advise you to look for scroll saws within your budget and start choosing using the above. It also goes back to the reason why you need the scroll saw. Simple tasks attract an average scroll saw, and complex projects require a versatile scroll saw that is not affordable.

Where to find scroll saws

You get scroll saws on the online shop or walk-in shops in your local area. Online shops like Woodcraft and NorthernTool have a wide range of scroll saws. You get the chance to compare prices and products before buying. There are manufacturers, suppliers, and exporters around the world that make your shopping easier.

Conclusion

A scroll saw is a small hand-held power tool that cuts intricate shapes out of wood. The basic design of a scroll saw hasn’t changed much since Mr. M’Duff patented it in 1869. Yet, the sizes and shapes of the blades have changed. Blades for scroll saws are different from blades for other woodworking tools, and that is because they have teeth that point down and away from the direction of the cut. You should also check out our Best Wood for a Scroll Saw shortlist.

- Grain and Sheen: Teak Oil versus Danish Oil Uncovered - January 10, 2024

- The Cherry on Top: Crafting the Perfect Cutting Board - January 9, 2024

- Polyurethane Water-Based vs Oil-Based: Choosing the Right Finish - January 8, 2024