How much does a Boxford lathe weigh?

ME10 (metric version) Boxford Metal Lathe with 127 mm Center Height and 560 mm between Centers. The motor is single phase and 240 volts. Weight is estimated to be around 141 kg (lathe only). It has the following measurements: 1450 mm x 850 mm x 1250 mm. A 3-jaw, self-centering chuck with reversible jaws, a Quick-change tool holder with one tool, a Parting tool holder, a Live center, a Tailstock drill chuck, a Swarf tray and stand, a Coolant Pump (requires some maintenance), and a Work Light are among the Boxford lathe’s accessories.

How much does a MyFord ML10 weigh?

A general ML10 with standard equipment and no motor weighs 53 kg, the rising blocks are 4.9 kg with the motor weighing 11.5 kg, according to the sales booklet of the period. Otherwise, you should be aware that the ML10 lathe emerged in 1968 as a low-cost yet high-quality machine tool. Its target market was slightly above several popular little lathes suitable for modeling and model engineering on a tiny scale.

The ML10’s capability was the essential attribute that set it apart from its competitors. Instead of gazing at a piece of material, you could machine it if you could physically fit it between centers. It has been developed numerous times since then.

How long is a MyFord Super 7 lathe?

The Imperial Super 7 lathe comes with a cabinet with a drip tray and lifting blocks. Although it has barely been helpful, it has been well-maintained and stored in a temperature-controlled workshop. It hasn’t been refurbished (not even touched up with paint). Our resident engineer has thoroughly inspected it and found it in perfect working order. It’s a Super 7 with a long bed (31″ between centers), perfect for instrument builders and gunsmiths. The size of a lathe matters a great deal when gunsmithing.

This lathe comes with an imperial quick-change gearbox, which provides 24 imperial/inch threads and 24 feeds combined with the 8TPI leadscrew. (The metric conversion kit is necessary for metric, BA, cables, and odd pitches). It includes a power crossfeed (facing), a tee-slotted cross slide, and the top slide swivels 360 degrees. The top and cross slide feedscrews have micrometer dials that you can adjust, and the apron comes with a thread dial indicator.

The barrel feedscrew has a three-start thread for quick movement, and the tailstock is self-ejecting. The barrel has a 2MT precise bore. You can set over the tailstock body on its base from either direction to turn long, shallow tapers. A countershaft clutch comes with the machine. The spindle is supported by a plain taper front headstock bearing, while axial loads get sponsored by a pair of angular contact ball races at the back. The nose of the spindle gets threaded at 1 1/8″ x 12 TPI. The bullwheel has 60 teeth and 14 speeds that range from 27 to 2105 revolutions per minute.

6 feet lathe machine weight

The 6-foot lathe machine is carefully developed and built to international standards under the supervision of qualified personnel. It weighs between 750 and 800 kilograms (kg). It’s a machine that’s in high demand in the business.

Lathe Machine Weight in kg

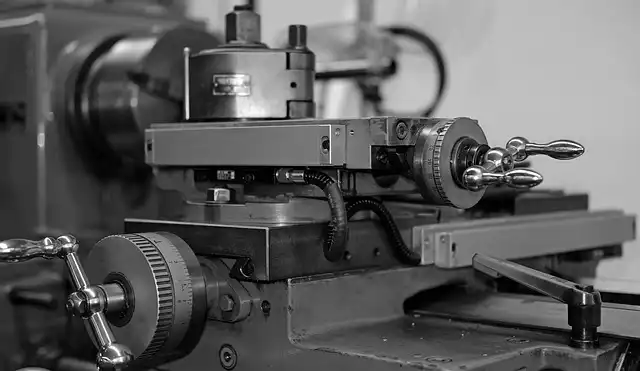

Heavy Duty Lathe Machines create symmetrical shapes around a rotational axis. Precision machining of rigid materials is done on these lathes. The devices include cutting-edge technology for increased performance. The machine is cost-effective and has robustness, durability, and efficiency attributes; the goods have great precision and accuracy.

These Heavy Duty Lathe Machines have specific characteristics such as ground headstock spindles and full one-piece planar lathe beds, which give a solid basis while simultaneously aligning the carriage and tailstock with the axis to allow seamless spindle movement. The alloy steel is employed to offer the machine potency and sturdiness for long-term durability. A specialized oil pump is necessary to lubricate the revolving spindles and bearings, allowing the machines to produce more power by neutralizing internal frictions and tensions within the lathe mechanism and cooling overheated parts.

For example, the weight of a lathe in kilograms depends on the technological parameters available;

SH-1 Model

- 1675 mm in length

- 430 mm for ABC (Admit Between Center).

- 1050 kg weight**

SH-2 Model

- 2135 mm in length

- 890 mm for ABC (Admit Between Center)

- 1200 kg in weight

SH-3 Model

- 2740 mm in length

- 1500 mm for ABC

- 1400 kg in weight

SH-4 Model

- 3050 mm in length

- 1800 mm for ABC

- 1650 kg in weight

Average weight wood lathe

Let’s start with a basic fact: “The Perfect Lathe” does not exist. The key to selecting the ideal lathe for you is determining what is most important. Whichever lathe you choose will be a compromise in one or more areas, such as price, size, features, quality, and so on.

Apart from performance and price, several factors to consider while purchasing the best lathe. Size, base, headstock, tailstock, power, speed, and capacity are the factors to consider. To begin your woodturning journey, you’ll also need the appropriate safety measures and equipment in your workshop.

Mini/benchtop, midi, and full-size lathes are available. The opposite could not be further from the truth. According to most experienced turners, a decent quality micro lathe is a serious tool well suited to a beginning turner wishing to learn the profession with minimal expense. For those who can’t afford to start with the iconic and elusive “Last Lathe I’ll Ever Own,” the small is a decent entry point.

Minis are perfect for bowls, vases, hollow forms, and other items with a diameter of 10′′ or 12′′. Is it essential to turn a bowl with a diameter greater than 12 inches?

Other factors to consider in terms of the size and weight of a wood lathe include:

The size likewise determines the maximum length of wood you can work on. The greater the lathe, the more weight it carries. The height of the lathe makes a difference as well. Because full-size lathes are often very heavy, weighing over 300 pounds, ensure your workshop flooring can withstand the weight.

The lathe’s spindle should be the same height as your elbows from the ground. If this is lower, you may bend over the machine, causing back pain. Aligning your tools becomes more challenging if it is higher. Because this is dependent on your height, and not everyone’s height is the same, you can raise the base of the lathe or stand on a platform to obtain the correct size.

Average weight metal lathe

The weight of a metal lathe is proportional to its size. A “normal” lathe weighs between 1500 and 3500 pounds, but a vast, heavy-duty lathe might weigh several tons. The weight of a small toolroom lathe is usually only a few hundred pounds.

For starters, there may be a pretty simple technique for determining this. Look over the instruction booklet for the machine. If you don’t have it, try searching for it on Google. Type the machine’s make and model in the search bar and “manual.” It should include basic information about your devices, such as their weight and lifting instructions.

For example, engine Size: Small to Medium Lathes are a step up from toolroom lathes and often have 13 inches or more swing. They usually weigh between 1,000 and 1,500 pounds. Here are a few instances:

A Jet 13-inch swing with 40-inch centers weighs over 1,200 pounds. Most people would consider this a little, light-duty machine. A Clausing Colchester with a 15-1/4′′ swing and 30′′ between centers (ubiquitous equipment in schools across the United States) weighs roughly 3,100 pounds.

It would be ideal to have a trailer. In other words, you transport most of the machines in this class’s lower to mid-range in the back of a pickup truck. On the larger ones, however, it’d be a little dicey.

- Pyrography Techniques for Beginners: Textures and Shading - January 23, 2024

- Troubleshooting Jointer Issues: Why is Your Jointer Not Flattening Wood? - October 11, 2023

- Unlocking the Secrets of Jointing to Increase Width - September 29, 2023