Can glass be machined?

CNC machining has been used for manufacturing glass for many years. CNC machines can provide users with distinct precision and flexibility when machining glass. You should be able to form various components beyond basic shapes safely. The products can manufacture glass and other optical materials without too much hassle.

Can you cut glass with a cnc router?

Suppose you need to perform a complex cut on glass that isn’t possible with regular glass. Difficult areas such as radiused corners and holes are manageable with a CNC router. You will need to attach a diamond burr or glass drilling bit for this project. Run this at rapid speeds but use a low feed. You need to ensure you have a substantial amount of coolant nearby as there is a lot of heating that will take place during the process. You will need to design a fixture to assist with holding the glass plate while you work. This fixture can be created out of any spare acrylic lying around.

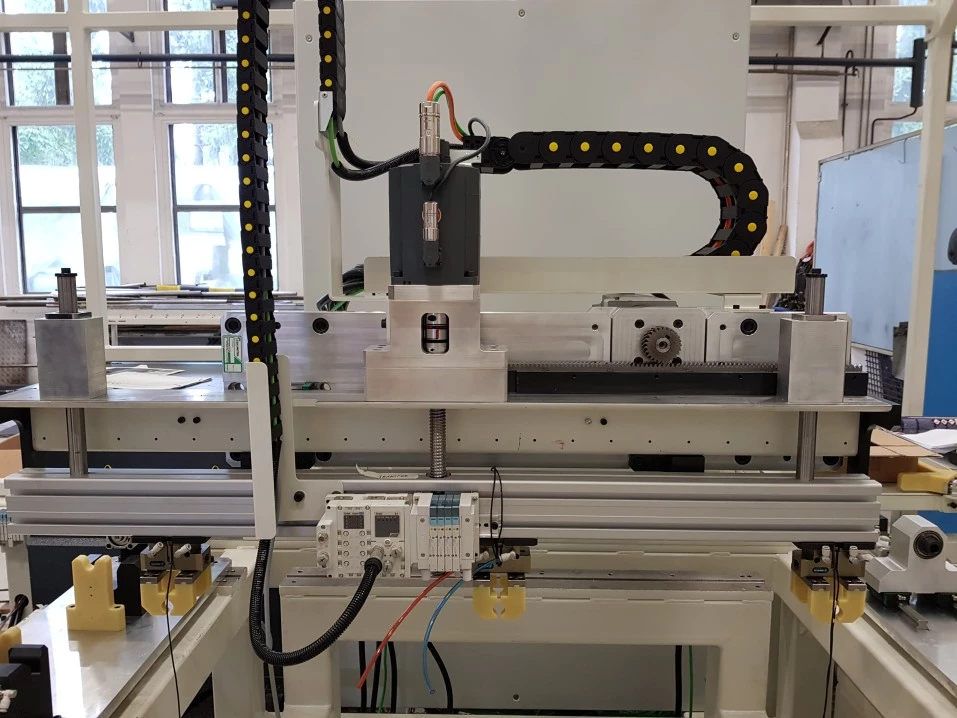

Cutting glass with a CNC

CNC has developed an innovative technology that uses three and four axes diamond tooling technology. This technology makes it easier to handle rigid glass material. You should be able to easily cut through quartz, high-pressure gauge glass, and furnace observation blue. The technology is quite advanced and should allow you to effortlessly execute projects that require materials in a wide range of shapes and sizes.

The giant machines available from CNC make it possible to process 27×48 inches in width and length of the glass. You can also drill up to 8 inches in thickness for more durable glass. Depending on the quality of glass you choose, precision CNC use should help you precisely fabricate parts with slots, holes or grooves. If you are pretty skilled in the craft, you should manage to taper your project to improve edge strength and cosmetics. Some of the glass you can cut on the machine includes Gorilla Glass, Teleprompter Mirror, Anti-Reflective & Non-Glare Glass, and Pattern glass.

Safety tips for milling glass

- Ensure that you have a pair of CSA-certified safety glasses that you wear religiously. These can protect your eyes from any flying shards of glass that can appear during milling.

- When working on a mill, it is good always to put on personal protective equipment (PPE). This gear can protect other parts of your body. An example of this is footwear or noise cancellers.

- You should be able to stop the machine at a moment’s notice. Before you start working, you need to make sure the start/stop button is close enough to reach easily.

- It is good to practise constantly checking that the emergency stop is accessible and working before you begin cutting.

- Check that both your glass and cutter are 100% secure. If these are not mounted correctly before a cut, they can come loose and cause injury.

- The best way to mount the glass is to bolt it or use a securely attached magnet to the work table.

- You should be wearing industrial gloves when handling milling cutters. It is also advisable to use a cloth to hold it and provide an extra buffer between you and the glass. This will prevent you from being cut when handling them.

- Ensuring the table is as far as possible from the glass cutter during the initial set-up phase is best to prevent any hand injuries.

- It is best to work from big to small areas.

- The revolving glass cutter should be distinctly out of the way from any brushes and rags. These can get caught in the machine and cause damage.

- Stop working regularly and vacuum clean any glass cuttings in the work area. Do this only when the glass cutters have wholly stopped rotating.

- Make sure that the cutter is sharp and positioned accurately. If not, the edge will direct the glass in the wrong direction.

- Always make sure the workspace is clean & tidy. Avoid having any scraps, tools and materials within 1 meter of you.

- Ensure the floor is clean and free of any machine grease/oil to avoid tripping.

- If you need to change your glass cutter, ensure that the power is off at the source before changing cutters.

- It would be best never to leave the machine unattended while in operation.

Cnc mirror cutting

Using a CNC glass cutting machine, it is possible to bend, curve and sandblast mirrors. The machines are quite advanced and should allow you to safely straight line polish your mirrors without hassle. It uses modern processing techniques that make it possible to process glass from 2 to 19mm thick. Mirrors can be efficiently designed and machined up to 6mm. These can then be cut into various shapes and sizes as required.

Buying a cnc for glass

Budget

CNC routers are pretty pricey given their wide range of functions. These machines will often cost between $2,500 to $200,000+. It is best to perform a cost analysis and ensure a sufficient return on investment before buying the product.

Size and Capacity

If you are still starting, it is best to choose a machine with a working area of 4×8. This should be able to handle most small-scale glass operations.

Accessibility

Consider the amount of space you have available in the workshop for the machine. Avoid trying to pile machines nearby of each other for safety reasons.

Can borosilicate glass be machined?

Borosilicate glass is well known for being brittle and hard. These qualities make it difficult for beginners to machine this glass. Even highly skilled machinists have to use non-conventional machining methods to handle this glass.

How do you cut glass without cracking it?

Water pressure cutting is a viable option when you need to cut glass delicately without breaking it. The technique makes use of high-pressure jets that cut through the glass seamlessly. It is the optimal option because it’s fast, and the water will also polish the glass.

Can a diode laser cut glass?

A diode laser will struggle to cut through the glass, but it is helpful for engraving on glass.

- 6 Tips To Craft The Perfect DIY Woodworking Project - August 1, 2022

- Six Reasons You Need an Air Filter In Your Wood Workshop - August 1, 2022

- American made wood lathes - May 26, 2022